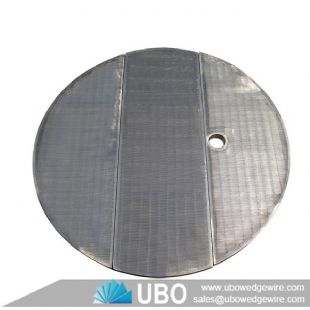

stainless steel catalyst bed supports

| Category: | Wedge Wire Screen Panel |

|---|---|

| Material: | Stainless steel 304, 316, 316L. Chromium-molybdenum alloy [2.25 Cr-1Mo], or as your need. |

| Properties: | wedge wire screen panel |

| Application: | petrochemical and refining industries |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of stainless steel catalyst bed supports

YUBO custom produces and manufactures stainless steel catalyst bed supports. Our catalyst bed support has the benefit of durable construction, precise open area, and is virtually non-clogging.

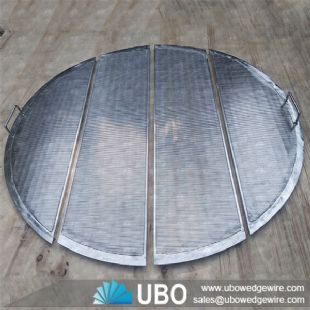

Support grids provide superior media retention characteristics in vessels of all types.

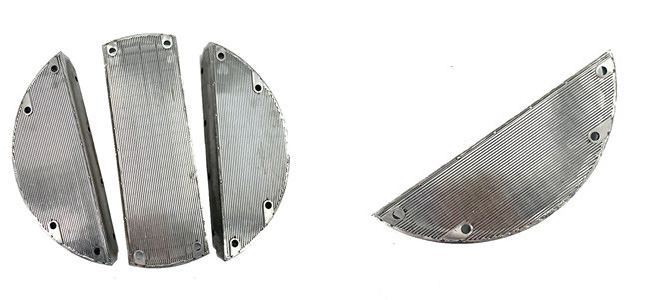

YUBO ss catalyst bed supports are generally manufactured with wedge wire profiles. Moreover, For larger vessel diameters our support grids are manufactured in sections to accommodate installation through manways.

Usages:

Used in petrochemical and refining industries. Hydrogenation reactor, desulfurization reactor, cracking reactor, reaction vessel, high-temperature shift reactor gas, desulfurization reactor, packing chemicals, molecular sieve...etc.

Advantage of stainless steel catalyst bed supports

Features:

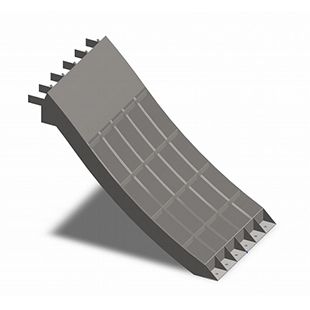

1. Satisfy enough high temperature and corrosion resistance. The industry characteristics of operation determine the performance of the product.

2. High mechanical strength. Even in hydrocracking and desulfurization reactors, it can easily resist collapse or bending.

3. Manufactured in sections, easy maintenance.

4. Self-cleaning function, high screening efficiency.

Factors to consider when designing

1. The weight of the catalyst support plate itself

2. Bed pressure drop and operating liquid weight

3. The structural dimensions of the support beam and grid

Specifications of stainless steel catalyst bed supports:

A complete vessel internal design includes an inlet basket, distributor laterals, support grid, and outlet basket collector laterals with backwash systems for efficient and effective operation.

Specifications can be customized according to your requirements

Packaging and Transportation of stainless steel catalyst bed supports: