wedge wire water well casing screen tube for filtration

| Category: | Wedge Wire Application |

|---|---|

| Material: | stainless steel 302,304,316,316L |

| Properties: | wedge wire screen |

| Application: | water,oil,petrochemical,solid filtration |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

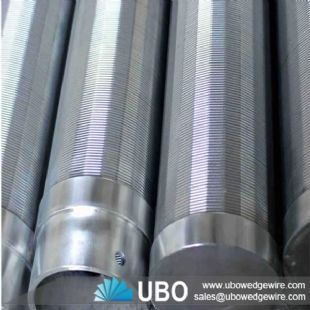

Details of wedge wire water well casing screen tube for filtration

This type of wedge wire water well casing screen tube is constructed by winding cold rolled triangular V-shaped wire around a circular array of longitudinal rods. the wire is welded to the rods and produces a rigid unit that has high strength and minimum weight.

The screen can be made in different height and width to address various strength application, meanwhile, the spacing of individual slots can be varied during fabrication if geologic conditions require these variations in a screen's construction.

Advantage of wedge wire water well casing screen tube for filtration

Screens with high open area are more suitable for the construction of high-quality water wells, oil wells and gas wells, avoids clogging and ensures an uninterrupted flow.Abundant water shall reduce the water level’s down, thus to save energy consumption

Screens have the features of easy backwashing, last long, safety and reliability as well as low comprehensive cost.

Reduce the abrasion of the pump.Under the same condition, high open area can make the speed of groundwater’s entering into the screen much slower than any other filtration apparatus, which will avoid sand’s entering into screen because of high pressure, thus reduce the abrasion of the pump.

Extend the life span of wells.Comparatively, groundwater’s entering into screen with higher open area is much easier than the entering into lower open area screen. The slow water flow shall extend the life span of wells.

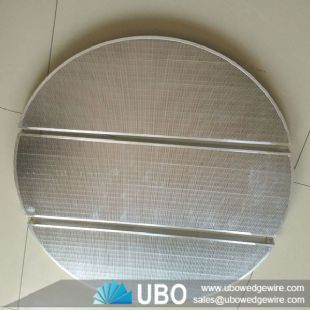

Application of wedge wire water well casing screen tube for filtration

The wedge wire water well screen is used throughout the world for water, oil, and gas wells, and for environmental well completions. It is the dominant screen type used in the water well industry.

The wedge wire water well screen is used throughout the world for water, oil, and gas wells, and for environmental well completions. It is the dominant screen type used in the water well industry

Specifications of wedge wire water well casing screen tube for filtration:

|

Specification (wedge wire): |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 |

|

Specification (support rod): |

Width(mm): 2.30 3.00 3.30 3.70 |

|

Note: other specifications available as per request |

|

|

Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material: |

galvanized low carton (LCG), stainless steel (304,316 etc.) |

|

Length |

up to 6 meters. |

|

Diameter |

from 25mm to 1200mm. |

|

End connection |

Plain beveled ends, flanged or threaded couplings |

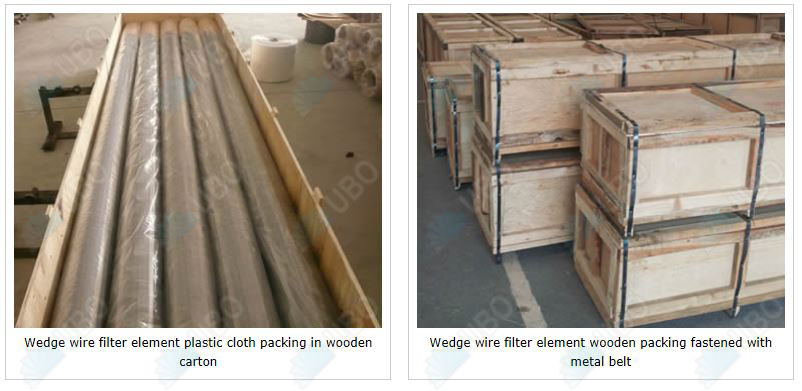

Packaging and Transportation of wedge wire water well casing screen tube for filtration: