wedge wire screen distributor for tank body

| Category: | Wedge Wire Application |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | wedge wire screen |

| Application: | water treatment, oilfield, mining, food industry, chemical industry, papermaking industry, decoration. |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

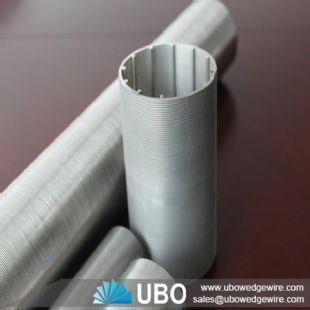

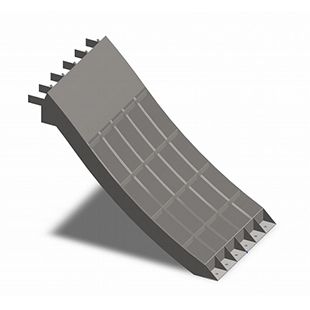

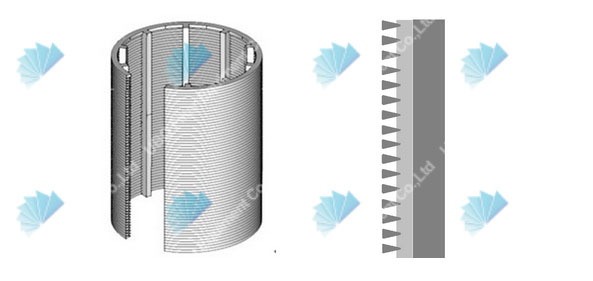

Details of wedge wire screen distributor for tank body

Wedge wire screen distributor has long been considered the most effective media for use in under draining. Wedge wire has an inherent even pattern if open area that allows for accurate flow distribution. Its internal support rod structure gives it a higher collapse strength allowing it to handle the most demanding load applications. Constructed of stainless steel and many exotic alloys wedge wire is easily worked to meet both typical and unique under drain designs. Although Concord Screen supplies arrange of standard wire shapes, an in house wire forming facility allows for custom shaping if required by design.

Advantage of wedge wire screen distributor for tank body

Large flow area

Uniform water distribution

High mechanical strength

Temperature resistance pressure resistance,

Pressure resistance

Aging resistance

Corrosion resistance

The resin still can’t flow out.

Application of wedge wire screen distributor for tank body

Wedge wire screen distributor can be designed for disc head vessels enabling the system to collect completely to the bottom of the vessel. Header Laterals design are also available for flat bottom vessel distributor or collector applications. Systems can be designed to accommodate side, center, top or bottom inlet piping. Integral backwash systems can be designed for any hub and header lateral for fast effective and efficient cleaning. Connections of the laterals can be flanged or threaded. All systems are designed for effective liquid or solid retention in a wide range of applications including exchangers, clay and sand filtration applications, carbon towers and power plants with water systems.

Specifications of wedge wire screen distributor for tank body:

|

Wedge Wire |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

|

Support Rod |

Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

|

Note: other specifications available as per request |

|

|

Slot Size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material |

galvanized low carton (LCG), stainless steel (304,316 etc.) |

Packaging and Transportation of wedge wire screen distributor for tank body: