wedge wire cylinder screen for industry process

| Category: | Wedge Wire Application |

|---|---|

| Material: | stainless steel 302,304,304L,316,316L |

| Properties: | wedge wire screen |

| Application: | water treatment ,oilfield,mining,water well,food,industry,filtration |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

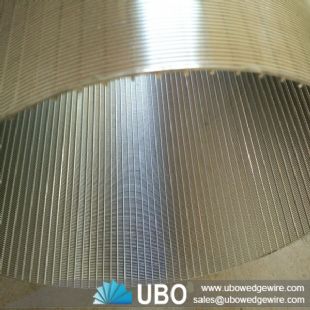

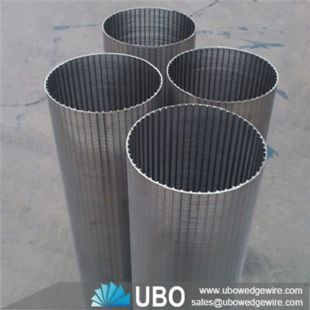

Details of wedge wire cylinder screen for industry process

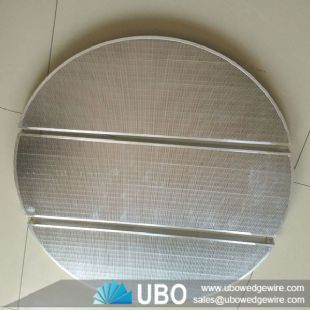

Compared with wedge wire screen tube, the wedge wire screen cylinder has some similarity and difference. Similarity of wedge wire screen cylinder and wedge wire screen tube They are all manufactured from stainless steel wire, including triangle surface profiles, round, rectangular, triangle and wedge wire support profiles. They are produced on an automotive machines, which the support profiles are welded onto surface profiles when the surface profiles are winding. Difference of wedge wire screen cylinder and wedge wire screen tube Wedge wire screen cylinder has larger diameters than the wedge wire screen tube. This make the wedge wire screen cylinder can be used in large machines and applications. Wedge wire screen cylinder has higher load capacity than the wedge wire screen tube. The wedge wire screen cylinder is commonly used in the heavy duty applications and maintain a long service life. Edge type of wedge wire screen cylinder Standard type. There is no any edge on the wedge wire screen cylinder. End ring type. The end rings are welded onto wedge wire screen cylinder. Flange type. The flange are welded onto the wedge wire screen cylinder and there are two types of flange for your choice.

Features of wedge wire cylinder screen for industry process

A continuous slot opening which significantly increases the available open area, thus providing a greater access to the water bearing zone.

Avoids clogging and ensures uninterrupted flow.

Ladder-like wire welded screens have the features of easy backwashing, last long, safety and reliability as well as low comprehensive cost.

Styles of connection: by welding or by threaded male/female coupling.

Standard length: 1m-5.85m

Uses of wedge wire cylinder screen for industry process

Cylinders are used as rotary screens, collectors such as screen laterals and nozzles, resin traps, in-line strainers, water intake screens, well screens, as well as many other applications involving liquid / solids separation.

Specifications of wedge wire cylinder screen for industry process:

Material:stainless steel

Type:cylinder screen

|

SLOT

(INCH) |

LENGTH

(m) |

WIDTH

(m) |

COLLAPSE

STERENG

(PSI) |

TENSILE

WEIGHT

(TON) |

WRAP

(thick*deep)

(mm) |

RODS

(mm) |

|

0.04 |

1-6 |

0.5-2 |

395 |

6 |

2.2*3.0 |

3.8mm/22 |

|

0.04 |

1-6 |

0.5-2 |

395 |

6 |

2.3*3.0 |

3.8mm/22 |

|

0.04 |

1-6 |

0.5-2 |

252 |

8 |

2.3*3.5 |

3.8mm/32 |

|

0.01 |

1-6 |

0.5-2 |

399 |

10.5 |

3.0*5.0 |

3.8mm/48 |

|

0.02 |

1-6 |

0.5-2 |

370 |

10.5 |

3.0*5.0 |

3.8mm/48 |

|

0.04 |

1-6 |

0.5-2 |

323 |

10.5 |

3.0*5.0 |

3.8mm/48 |

|

0.01 |

1-6 |

0.5-2 |

206 |

11 |

3.0*5.0 |

3.8mm/50 |

|

0.02 |

1-6 |

0.5-2 |

191 |

11 |

3.0*5.0 |

3.8mm/50 |

|

0.04 |

1-6 |

0.5-2 |

167 |

11 |

3.0*5.0 |

3.8mm/50 |

Packaging and Transportation of wedge wire cylinder screen for industry process: