316L Stainless Steel Water Treatment Filter Nozzle With M24 End Fittings

| Category: | Wedge Wire Application |

|---|---|

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | Filter Nozzle |

| Application: | waste water filtration, pulp and paper as well as mineral processing applications. Wedge wire or profile screen half cylinders can be added to an aug |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of 316L Stainless Steel Water Treatment Filter Nozzle With M24 End Fittings

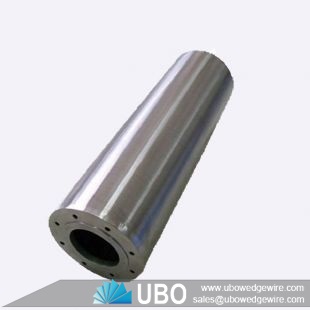

316L Water Filter Nozzle are widely used in various industries, especially suitable for water treatment or liquid filtration.The main part of the nozzle is stainless steel wedge wire screen . It’s a new type filter component. The filter nozzle has a high precision fitration ability . The minimum slot size is 20 micron.

Usages for 316L Stainless Steel Water Treatment Filter Nozzle With M24 End Fittings:

Stainless Steel wedge wire water treatment filter nozzle with thread coupling can be fixed on the filtering equipment for the filteration of water petrol resin and other medium. Also it can be used in the water treatment, water softhening, conversion of sea water into fresh water, the filter of food chemistry.

Construction for 316L Stainless Steel Water Treatment Filter Nozzle With M24 End Fittings:

1) We use wedge-shaped profile wire in order to make the slot v-shaped.It can stop the impurities very well.

2) The wedge wire was welded on the support wire well-proportioned and have perfect roundness. Ensure the screen have bigger filter area and non obstructive, avoid the high concentration of impurities.

3) After work for a period of time, the filter can be back flush.It has a long life.

Features for 316L Stainless Steel Water Treatment Filter Nozzle With M24 End Fittings:

-- Reduced costs, since wedge wire screens have a very long life.

-- Greater resistance to stresses of different pressure and temperature.

-- Maximum effective flow area & operating efficiency is maintained

-- Costly downtime for cleaning plugged screens is minimize.

-- Technology for wedge wire screen filter nozzles Composite ion exchanger:

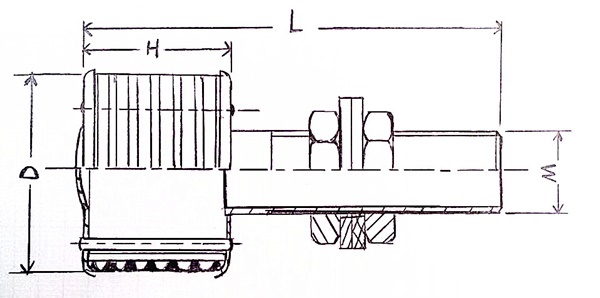

Specifications of 316L Stainless Steel Water Treatment Filter Nozzle With M24 End Fittings:

|

No. |

Type |

Ton |

Slot Opening |

Size |

0.2-0.25mm slot opening Area of through-flow mm2 (reference) |

|||

|

D |

L1 |

L |

M |

|||||

|

1 |

TYS45-1-C |

0.5 |

0.2-0.5 |

45 |

45 |

95 |

24 |

500 |

|

2 |

TYS53-2-B |

1 |

0.2-0.5 |

53 |

45 |

100 |

24 |

570 |

|

3 |

TYS53-2-C |

1.5 |

0.2-0.5 |

53 |

50 |

110 |

32 |

700 |

|

4 |

TYS57-3-B |

2 |

0.2-0.5 |

57 |

45 |

110 |

32 |

600 |

|

5 |

TYS70-4-B |

3 |

0.2-0.5 |

70 |

55 |

120 |

32 |

1000 |

Packaging and Transportation of 316L Stainless Steel Water Treatment Filter Nozzle With M24 End Fittings: