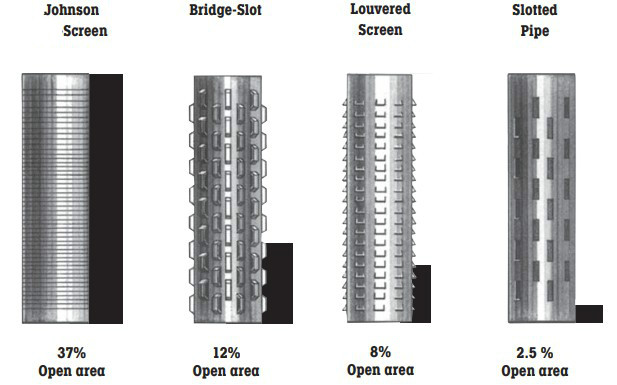

Wedge Wire Screen Has More Open Area

The amount of open inlet area in the screen directly affects the volume of water that the well can produce. Comparing various screen types of the same diameter and slot opening, It shows that Wedge Wire screen has vastly greater open area, allowing more water to enter more easily.

More open area makes better well development possible

Comparing with the four screen types showed above, wedge wire screen provides the best access to the formation for optimum well development. High open area is vital for thorough development or cleaning after drilling. When drilling the well, damage will occur to the aquifer when the permeability in the vicinity of the borehole is reduced by the invasion of fine silt and clay and by the mixing of the formation particles by the action of the drill bit. The well cannot performance efficiently unless the damage is repaired. Development is done by surging, water jetting or some other mechanical means of removing the fines from the formation around the screen. The effectiveness of this process is directly related to the open area of the screen, since the development tools must have access to the formation and the gravel pack. UBO wedge wire screen are more easily and thoroughly developed than wells using slotted pipe, bridge slot screen or louvered screen because of it's greater open area.

The opening ratio of wedge wire screen is very important, which affects its working efficiency. There are two ways to increase the opening ratio: one is to increase the diameter of the mesh hole, and the other is to reduce the center distance of the mesh hole.

The former will increase the particle size of the feed item and reduce the uniformity, which will weaken the strength of the sieve. On the sieve plate shearing mold, except for the special case, the normal sieve plate edge does not have a front angle and a back angle. At the same time, its sharpening is not as complicated as cutting tools. On one hand, the strength of the cutting edge is considered, and the convenience for mold making and sharpening is considered. On the other hand, considering the sieve, even if the shape of the cutting edge is changed, a good result may not be obtained. In actual production, the diameter of the mesh hole is determined by the feeding object.

Therefore, when selecting the sieve, the requirement for the particle size should be considered first. According to the strength of the sieve, the large-aperture sieve should be selected as much as possible to improve the pulverization efficiency and save. Energy consumption.

So what are key factors in choosing wedge wire screen material

1) Good stamping performance

Stamping performance refers to the adaptability of sheet metal to various stamping processing methods. For example, the stamping processing method referred to good plasticity when material is plastic.

2) Thickness tolerance in accordance with national standards

The mold clearance is determined by the thickness of the material. Therefore, the material thickness tolerance should conform to the national standards. Otherwise, if thickness tolerance is too large, the quality of the workpiece will be affected and there might be damage to the mold and the equipment.

3) Good surface quality

Good quality surface materials is needed, so that the workpiece is not easy to break when the screen plate is stamped, and the waste is reduced. The

mold is not easy to scratch, thus the working life is improved.