Manufacturing process of wedge wire products from UBO

Manufacturing process of wedge wire products from UBO

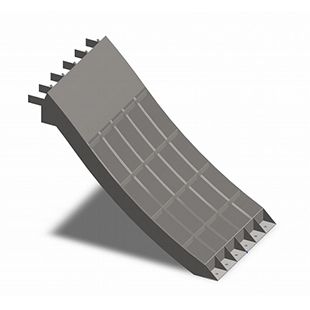

The manufacturing process of wedge wire products is a two step process. The first stage consists of preparing the V-Shaped wall material. This process consist in creating a material in a triangular shape (V-Shaped) that provides uniformity and the needed resistance according to the requirements of the different products. Then, the external material (V-Shaped) is welded to the body or framework material using a continuous welding system. In both manufacturing processes, specific machinery is needed.

The machinery utilized to our wedge wire products have designed and built by our own team of engineers. The fact of manufacturing with our own in-house built equipment, allow us to easily modified or expand our productive capacity in a minimum period of time with the purpose of fully comply with our clients orders on time.

UBO has 10 years of experience in the field of manufacturing wedge wire products. Through the time, we have considerably improved our products with the purpose of offering a high quality product at a very competitive price.

Our technology allows us to produce continuous slot water well screens and wedge wire screen drum or cylinders with diameters at customers' requirement. Our products are produced from low carbon steel, carbon steel galvanized, stainless steel, copper, high resistance alloys, and corrosion resistant high-strength alloy.

Our extensive experience allows us to provide to our customer with products of the highest quality at very competitive prices. Our main commitment is to work closely with our customers with the goal of providing cost efficient solutions and a fast response to their needs and operating problems.

Our productive capacity and experience allows us to offer a full range of different screens and customized engineered products to meet the most demanding requirement for different projects. If you can draw it, we can build it.

Our own productive and distributing capacity allow us to respond in a quickly and efficient manner to our international clients.

Benefits of continuous slot wedge wire screens are many, among some of those are:

1) Continuous slot screen offers a larger opening (filtering) area, which lead to a larger production of the water well.

2) A greater opening area (filtering area) reduces the pressure in the systems and head loss, thus, energy consumption was reduced.

3) Minimal water frictional head loss contributes to an increase in the efficiency of the water well and/or filtering systems.

4) Elimination of the problems associated with pumping of fine sands in water wells. Longer working life of the system.

5) In the case of water screens, these are self-cleaning, which leads to a reduction of the maintenance cost and longer life of pumping equipment.

6) Stainless steel or galvanized wedge wire screens offer a greater resistance to accelerated corrosion.

7) Minimum failure risk in the construction process especially in wells built in thin aquifers.

8) Failure risk reduction of the filtering system.

9) Products design can be easily adapted to any specific project at a minimum cost