wedge wire screen for purified wanter treatment

| Category: | Wedge Wire Application |

|---|---|

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | Wedge Wire Pipe |

| Application: | filters, strainers, architectural screens, water treatment underdrains, media support grids and overlays |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of wedge wire screen for purified wanter treatment

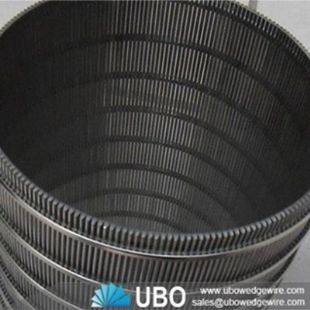

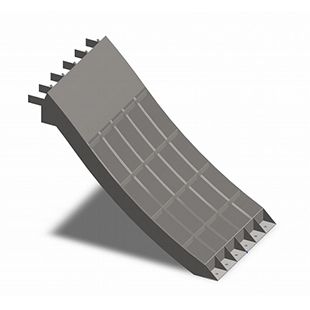

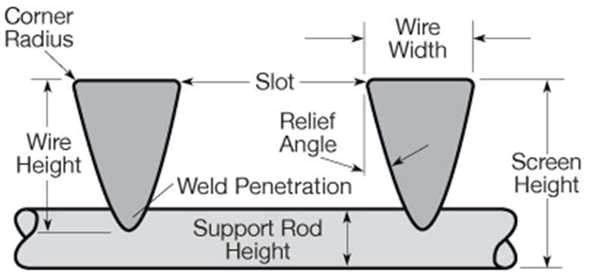

1. Wedge wire screens(wire wrapped screens)are manufactured by a v or wedge shaped wire around an internal array of longitudinal support rods.

2.The world advanced all-weld technology is used with each intersection point of these wire fusion welded, which creates the robust construction and excellent mechanical performance.

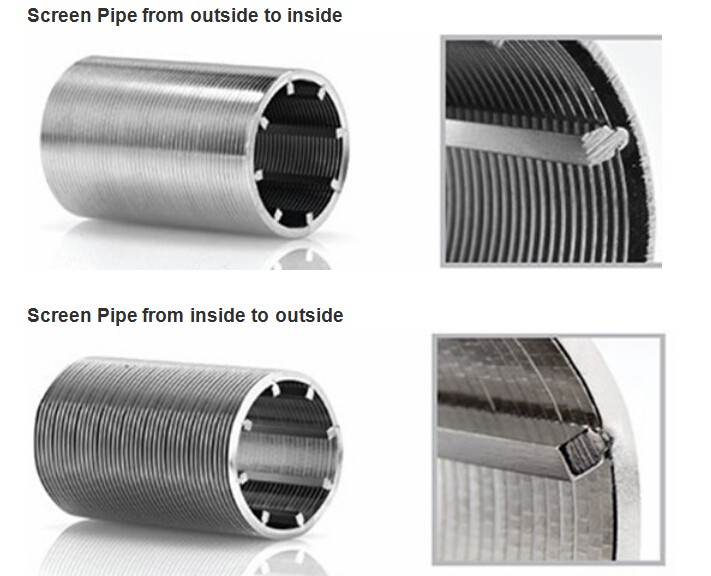

3.The v or wedge shaped profile wire wraps around the support rods over the full length of the screen creating a continuous slot opening, hence the screen allows water(oil) to enter your well freely in ample quantities, while at the same time keeps the majority of sand and gravel out of the well.

The slots can be changed and manufactured according to different strata.

Characteristics for wedge wire screen for purified wanter treatment:

The benefit of wedge wire screen is more open area, have very precise openings ,maximum design flexibility, stronger and more durable, economical ,easier installation and long-term operating etc.

Application for wedge wire screen for purified wanter treatment:

wedge wire screen is widely used in filters, strainers, architectural screens, water treatment underdrains, media support grids and overlays, infiltration gallery screens, lauter tun screens,many other liquids, solids separation applications.

Advantages for wedge wire screen for purified wanter treatment:

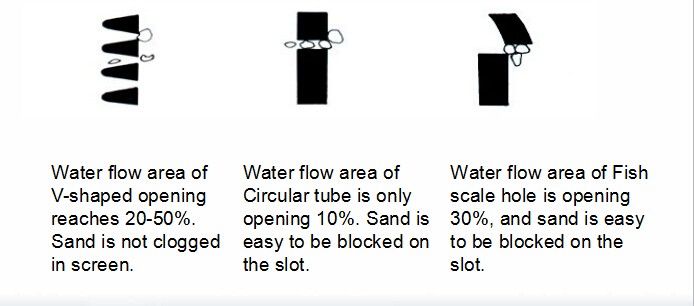

1. Non-clogging construction.

2. Large Filtering Area.

3. Increase the water yield and prolong service time of the well.

4. Long service life Wire and support rods are all-welded, which makes wedge wire screens (Wedge Wire types screens) more robust and longer life.

5.Excellent construction strength.

6.Specifications and end connections of wedge wire screens can me fabricated according to customers’ requirements.

Common flow styles of different screens:

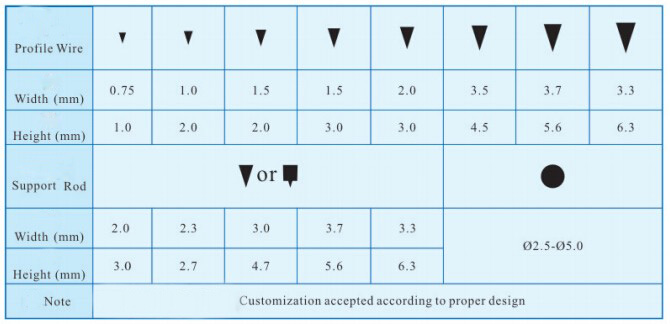

Specifications of wedge wire screen for purified wanter treatment:

|

Specification (wedge wire): |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

|

Specification (support rod): |

Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

|

Note: other specifications available as per request |

|

|

Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material: |

galvanized low carton (LCG), stainless steel (304,316 etc.) |

|

Length |

up to 6 meters. |

|

Diameter |

from 25mm to 1200mm. |

|

End connection |

Plain beveled ends, flanged or threaded couplings |

Packaging and Transportation of wedge wire screen for purified wanter treatment: