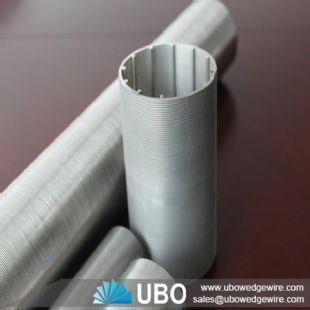

stainless steel strainer lateral nozzle pipe for filtration

| Category: | Wedge Wire Application |

|---|---|

| Material: | stainless steel302, 304, 316, 316L |

| Properties: | wedge wire screen |

| Application: | water treatment ,oilfield,mining,water well,food,industry,filtration |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of stainless steel strainer lateral nozzle pipe for filtration

Stainless steel strainer lateral nozzle pipe is manufactured by wrapping a shaped wire around an internal array of longitudinal rods and are joined by resistance welding. Screen sections are usually twenty feet long. Most continuous wire wrap screen is manufactured from stainless steel rather than carbon steel in order to avoid problems which often lead to accelerated corrosion.

Advantages of stainless steel strainer lateral nozzle pipe for filtration

Non clogging: V shaped profile wire, avoids clogging, is self-cleaning and ensures an uninterrupted flow. Sand grains make only two point contact and do not wedge in the screen's inwardly enlarging slot.

Large open area: This allows more water to enter at much lesser frictional head loss and the efficiency of well is improved appreciably.

High Strength: It takes stainless steel as main raw material, then is welded at high temperature, which guarantee high strength to bear big water pressure, hereby it has long life span.

Applications of stainless steel strainer lateral nozzle pipe for filtration

Stainless steel strainer lateral nozzle pipe connected to either a central-header pipe or a hub, they are important components of ion exchange units, media filters, sand filters, carbon strip vessels, carbon towers, clay filters and in many water and waster water treatment applications

Specifications of stainless steel strainer lateral nozzle pipe for filtration:

| Type | Slots mm | ΦA | Flange DN | L1mm |

| AM1 | 0.05, 0.1, 0.2, 0.3, 0.5, 1.0 | 45, 57, 76, 89, 108, 133, 159, 219 | 40, 50, 65, 80, 100, 125, 150, 200 | 442, 496, 547, 600, 654, 705, 758, 812, 863, 916, 970, 1021, 1074, 1128, 1179, 1232, 1286 |

| Type | Slots mm | ΦA | ΦB | L1mm | L2mm |

| AM | 0.05, 0.1, 0.2, 0.3, 0.5, 1.0 | G2" | Φ50 | 30,55 | 73, 126, 180, 231, 284, 338, 389 |

| G1 1/2" | Φ38 | 30,55 | |||

| G2" | 1 1/4"NPT | 30 | |||

| G2" | 1 1/2"NPT | 30 | |||

| Φ68 | G2" | 30 | |||

| 1 1/2"NPT | 1 1/4"NPT | 30 | |||

| 2 1/2" | Φ60 | 20 |

Packaging and Transportation of stainless steel strainer lateral nozzle pipe for filtration: