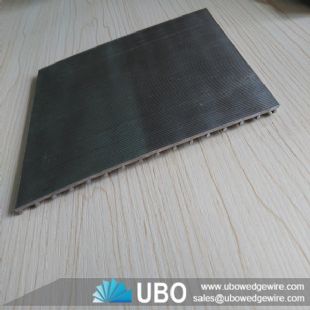

stainless steel Wedge Wire screen panel for filtration

| Category: | Wedge Wire Application |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | wedge wire screen |

| Application: | water treatment, oilfield, mining, food industry, chemical industry, papermaking industry, decoration. |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of stainless steel Wedge Wire screen panel for filtration

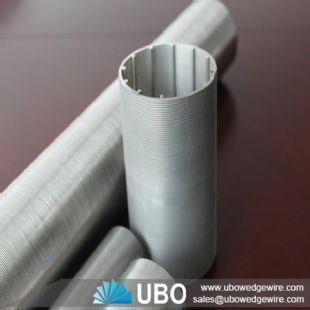

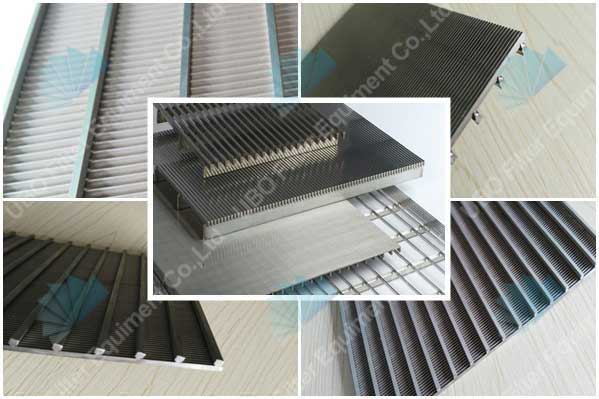

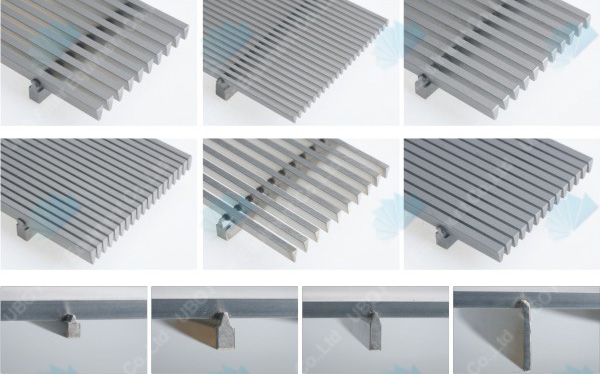

The V-shaped wire can be made in different height and width to address various strength application, meanwhile, the spacing of individual slots can be varied during fabrication if geologic conditions require these variations in a screen's construction.

Our stainless steel wedge Wedge Wire screen panel are all custom made and can be designed and built to fit any screening equipment in any specified width and length. Need a stainless steel flat panel screen on an extra-large scale? No problem. Plus, size, shape and spacing of profile wire are engineered to meet your special job requirements. Individual wire on the working surface of each wedge wire flat panel screen can be manufactured at a tilt to better serve your needs

Advantage of stainless steel Wedge Wire screen panel for filtration

-- A continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone.

-- A “V”shaped profile wire which avoids clogging and ensures an uninterrupted flow.

-- A uniform and efficient well development due to the continuous slot opening.

-- Wedge wire welded screens have a strong structure and high open area, as well as accurate slot dimension.

-- Profile wire welded screens have the features of easy backwashing, last long, safety and reliability as well as low comprehensive cost.

Features of stainless steel Wedge Wire screen panel for filtration

stainless steel wedge Wedge Wire screen panels are made from V shaped profile wire, with an unique welding process, offering great strength, precision, long service life and a wide range of applications in the field of process, engineering such as sugar juice filtration, waste water treatment, crude oil and natural gas production and vessel internals solving problems of solid / liquid and solid / gas separation, filtration of oils, greases, paints, food products, water, fuels, liquid cooling agents, chemicals etc.

Wedge Wire ScreenWedge wire can replace conventional media like wire mesh cloth, perforated plate and other metal sifting materials as components for rotary screen, well screen, quarry screen, etc.

Applications of stainless steel Wedge Wire screen panel for filteration

-- Separating;

-- Sizing;

-- Straining;

-- De-watering;

-- Filtering

-- Drying;

-- Water intake;

-- Media retention

Specifications of stainless steel Wedge Wire screen panel for filtration:

Slot size (mm): 0.025mm 0.10, 0.15, 0.2, 0.25, 0.30-3mm

Open area: up to 60%

Width: ranging from 25 to 800mm

End connection: plain beveled ends for butt welding or threaded

Material: Low Carbon Galvanized ( LCG ) and Stainless Steel (SS)

Slot (mm): 0.025 0.1、0.25、0.50、0.75、1.00、1.50、2.00、3.00 and so on.

Packaging and Transportation of stainless steel Wedge Wire screen panel for filtration: