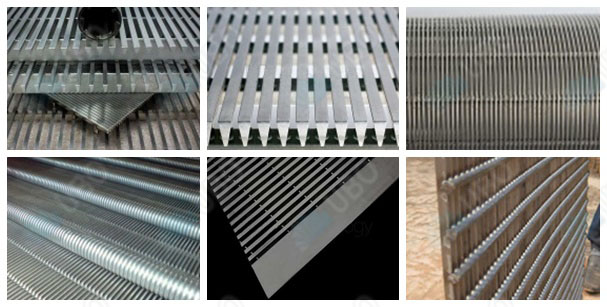

stainless steel V wire Wrapped Wedge Wire Water Well Screens

| Category: | Wedge Wire Application |

|---|---|

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | Wedge wire screen |

| Application: | water treatment equipment, environment protection, the sea water desalination, water softening treatment, oil and chemical processing |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of stainless steel V wire Wrapped Wedge Wire Water Well Screens

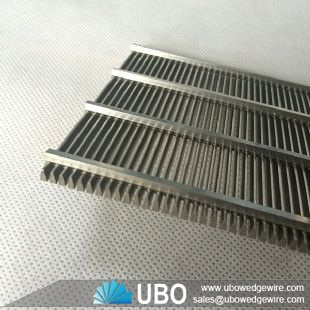

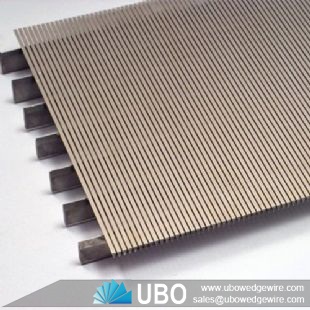

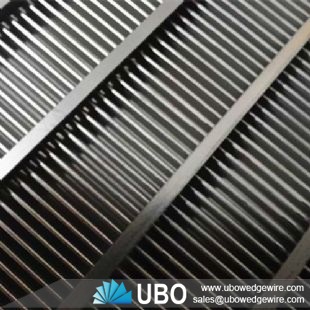

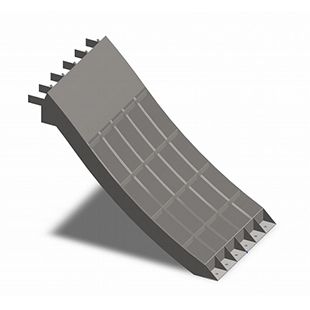

Wedge wire screen with V profile is engineered in various forms of filtering elements or cartridges in flow control. The mostly found shapes in uses are stainless steel wedge wire panels, cylinders, baskets, tubes and curved sieve bend in arc forms. Mainly serve mine, coal development, water treatment and well screening industries.

Application for stainless steel V wire Wrapped Wedge Wire Water Well Screens:

Flat panel screen can be parts of deep well pumps or submersible pumps; can be used for water treatment equipment, environment protection, the sea water desalination, water softening treatment, oil and chemical processing; terminal filtration for petroleum products, filtration for chemical acid and soda liquid, for alcohol and other organic solvents recycle filtration.

Features for stainless steel V wire Wrapped Wedge Wire Water Well Screens:

Accurate slot gap, high efficiency performance, stable structure, anti-high temperature, anti-corrosive, good mechanical properties, long-lasting and durable, safe and reliable, various field can be applied.

Advantages for stainless steel V wire Wrapped Wedge Wire Water Well Screens:

When compared to conventional slotted pipe, wire wrapped wedge wire screens have superior open area due to their continuous slot openings. The benefits of which will:

. Reduce energy consumption and increase water flow.

. Reduce erosion of entry surfaces and increase well life.

. Allow a uniform and efficient well development.

. Reduce significantly potential pump damage and subsequent maintenance costs.

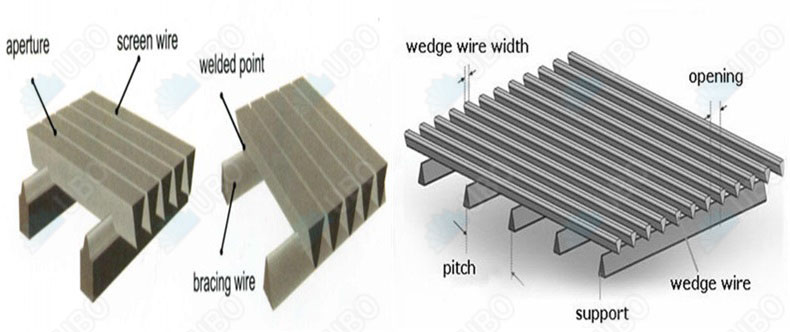

Specifications of stainless steel V wire Wrapped Wedge Wire Water Well Screens:

|

Specification (wedge wire):

|

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70

Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00

|

|

Specification (support rod):

|

Width(mm): 2.30 3.00 3.30 3.70

Height(mm): 2.70 3.60 4.70 5.60 6.30

Round: From 2.50mm to 6.0mm

|

|

Note: other specifications available as per request

|

|

|

Slot size

|

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request.

|

|

Material:

|

galvanized low carton (LCG), stainless steel (304,316 etc.)

|

|

Length

|

up to 6 meters.

|

|

Diameter

|

from 25mm to 1200mm.

|

|

End connection

|

Plain beveled ends, flanged or threaded couplings

|

Packaging and Transportation of stainless steel V wire Wrapped Wedge Wire Water Well Screens: