stainless steel V Wire Water Well Screen Mining Screen

| Category: | Wedge Wire Application |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | stainless steel wire mesh |

| Application: | vibrating screen decking,mineral processing, surface water intake screens, fish diversion screen panels |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of stainless steel V Wire Water Well Screen Mining Screen

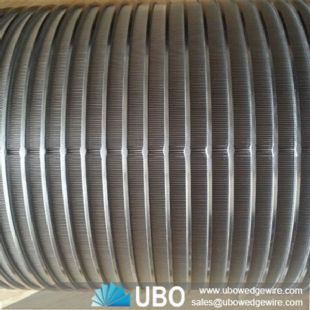

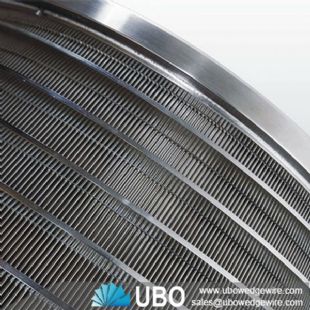

Our V-shaped wire water well screen, welded at each intersection point with the V-shaped around the wire and V-shaped ribs(or circular ribs).With the firm structure, high porosity, accurate slot size, especially suitable for the well fine sand and powder sand strata.The filter has the high proportion of filter area, maximum up to 60%.V-wire screen pipe is easy to reverse wash, long service life, safe and reliable, and low comprehensive cost.

Appliction for stainless steel V Wire Water Well Screen Mining Screen:

Applications for wedge wire screen panels include cross flow sieves, vibrating screen decking,mineral processing, surface water intake screens, fish diversion screen panels, hatchery screens, food processing, and flooring for malt kiln, germination, and grain drying.

Advantages for stainless steel V Wire Water Well Screen Mining Screen:

1. This type screen can be successfully applied for gravel packing and sand prevention. It enables the oil well to offer large output. And this product is not limited to the length of well section, bottom hole temperature or pressure.

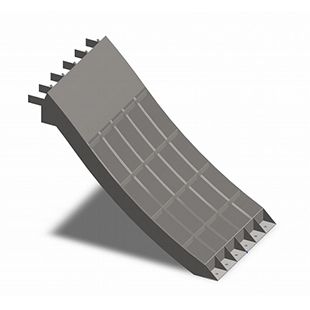

2. The utilization of trapezoid wrapping wire contributes to the formation of V-shaped openings between the seams. This design pattern makes the water to be filtered smoothly, thus improving the efficiency.

3. The wrapping wire is connected to all the supporting wires by welding. It can be used for a long time. In addition, both dense and uniform seams will be formed after this trapezoid wrapping wire has been wrapped onto the circumferentially arranged supporting wires. Those seams offer a large flow area while ensuring the excellent anti-blocking performance. Also, they will effectively help avoid sediment accumulation. Consequently, high production efficiency of the water well can be significantly improved, and the lifespan can be prolonged as well.

Working Principle for stainless steel V Wire Water Well Screen Mining Screen:

Inside the well, the all-welded wedge wire water screen is placed into the sand stratum. Then the gravel slurry together with the oil will be pumped into the space between the screen pipe and well. Through the multistage filtering, sand and gravel will be removed. Simultaneously, oil will get into the pipe from the holes, and then it will be continuously lifted to the ground. The sand will be controlled to turn back to the sand stratum, thus ensuring the normal production of the well. Moreover, the screen has no damage to the oil layer.

Filter Principle for stainless steel V Wire Water Well Screen Mining Screen:

To prevent sand, this type of screen uses the ring-like seams, which are formed by the spirally twisted stainless steel wire, which comes with cross section of isosceles triangle or trapezoid,. The seams with the trapezoidal cross section will not be blocked by the sand, thus allowing the good sand-prevention effect and longer service life.

The conventional well usually uses the wedge wire water screen to prevent the filled gravels, and uses the seams formed by the gravels to resist sand.

Specifications of stainless steel V Wire Water Well Screen Mining Screen:

|

Slot

mm

|

Opening

%

|

Weight

Kg/㎡

|

Slot

mm

|

Opening

%

|

Weight

Kg/㎡

|

Slot

mm

|

Opening

%

|

Weight

Kg/㎡

|

|

0.25

|

14.3

|

22.0

|

0.25

|

10.2

|

25.9

|

0.25

|

8.2

|

30.8

|

|

0.30

|

16.7

|

21.5

|

0.30

|

12.0

|

25.4

|

0.30

|

9.7

|

30.3

|

|

0.35

|

18.9

|

21.0

|

0.35

|

13.7

|

24.9

|

0.35

|

11.1

|

29.8

|

|

0.40

|

21.1

|

20.5

|

0.40

|

15.4

|

24.4

|

0.40

|

12.5

|

29.3

|

|

0.50

|

25.0

|

19.5

|

0.50

|

18.5

|

23.9

|

0.50

|

15.2

|

28.8

|

|

0.75

|

33.3

|

18.1

|

0.75

|

25.4

|

22.0

|

0.75

|

21.1

|

26.9

|

|

1.00

|

40.0

|

16.1

|

1.00

|

31.3

|

20.5

|

1.00

|

26.3

|

25.4

|

|

1.25

|

45.5

|

15.1

|

1.25

|

30.2

|

19.5

|

1.25

|

30.9

|

23.9

|

|

1.50

|

50.0

|

14.2

|

1.50

|

40.5

|

18.1

|

1.50

|

34.9

|

23.0

|

|

2.00

|

57.1

|

12.2

|

2.00

|

47.6

|

16.6

|

2.00

|

41.7

|

21.0

|

|

6.00

|

-

|

-

|

6.00

|

73.2

|

10.3

|

6.00

|

68.2

|

13.2

|

|

8.00

|

-

|

-

|

8.00

|

-

|

-

|

8.00

|

74.1

|

11.2

|

Packaging and Transportation of stainless steel V Wire Water Well Screen Mining Screen: