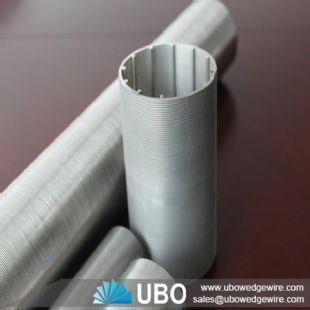

stainless steel All-welded wire-wrapped screen

| Category: | Wedge Wire Application |

|---|---|

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | Wedge Wire Cylinder |

| Application: | food processing, waste water filtration, pulp and paper as well as mineral processing applications |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of stainless steel All-welded wire-wrapped screen

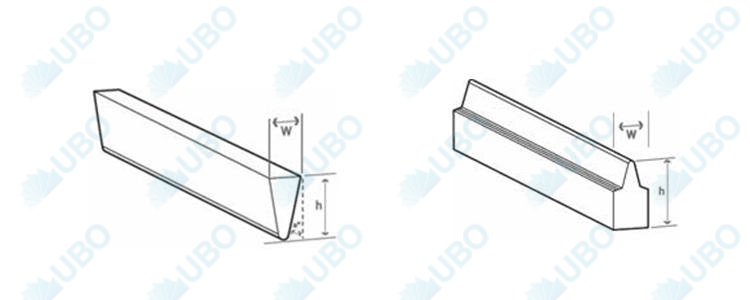

The Stainless steel wrapped screen pipe is made up of rods and wrap wire. The rod can be triangular wire or trapezoid wire. The wrap wire is triangular wire (Wedge Wire).

Stainless steel wrapped screen pipe has a delicate structure and high open area, as well as accurate slot dimension. At the same time, it has characteristics of heat-resisting, anti-corrosive, good machine capability, long service life, safety and reliability and so on. It can be used in many kinds of medium filtering. Such as oil, chemical acid, the alkali liquid filters, the ethyl alcohol, etc.

Uses for stainless steel All-welded wire-wrapped screen:

The strainer is a kind of filtered water tubing with the perforation .it can use with the deep well pump, dive the water pump, also may use in the water-treating equipment, the environmental protection, the sea water transforms into the industrial water and life use water desalination treatment, running water treatment, water softening treatment, the petroleum industry: The petroleum product terminal filters and the chemical acid, the alkali liquid filters, the ethyl alcohol and so on the organic solution recycling filters.

Advantage for stainless steel All-welded wire-wrapped screen:

•A continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone.

•A “V”shaped profile wire which avoids clogging and ensures an uninterrupted flow.

•A uniform and efficient well development due to the continuous slot opening.

•Ladder-like wire welded screens have a strong structure and high open area, as well as accurate slot dimension.

•Ladder-like wire welded screens have the features of easy backwashing, last long, safety and reliability as well as low comprehensive cost.

Manufacture all-welded wire wrapped screen

The wedge wire water well screen is used throughout the world for water, oil, and gas wells, and for environmental well completions. It is the dominant screen type used in the water well industry.

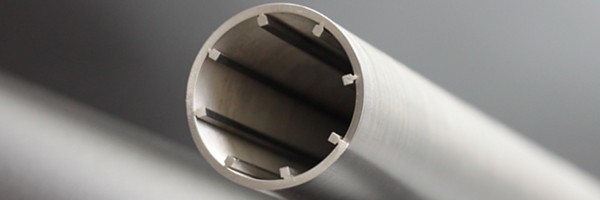

The welded stainless steel water well screen is made up of rods and warp. The rod can be round wire, triangular wire or trapezoid wire. The warp is triangular wire (Vshaped wire). Water well screens have a structure and high open area, as well as accurate slot dimension. At the same time, water well screen have heat-resisting, anti-corrosive, good machine capability, last long, safety and reliability and so on characteristics. It can be used in many kinds of medium filtering.

V-slot Features

The Continuous slot screens are made of V-shape wire or wedge shape wire around an internal array of longitudinal support rods. Each jointpoint of these wire is fusion welded, the V or wedge shaped profile wire wraps around the support rods over the full length of the screen creating a continuous slot opening. Therefore the screen allows water or oil to enter the well freely in ample quantities while keeps the majority of sand and gravel out of the well at the same time.

Slot Section

Continuous slot: support rods and longitudinal wire makes an opening which significantly increase the available opening area, and allow better access to the water flow.

High open area: reduce the water level, thus to save energy consumption. Meanwhile, high open area can make the groundwater enter the screen much slower than other filtration apparatus, which can avoid sand from entering screen due to high pressure, hereby lowering pump wear down.

High Strength: It takes stainless steel as main raw material, then is welded at high temperature, which guarantee high strength to bear big water pressure, hereby it has long life span.

Common flow styles of different screens

Structure Options

Specifications of stainless steel All-welded wire-wrapped screen:

|

Outside Diameter

|

Profile wire

|

Rod wire

|

Rod quantity

|

Slot size

|

Length

|

||

|

DN

|

Inch

|

mm

|

mm

|

mm

|

|

mm

|

mm

|

|

20

|

3/4

|

26.9

|

1.5*2

|

2*3

|

12

|

0.1~0.25

|

45~3000 |

|

25

|

1

|

33.7

|

1.5*2

|

2*3

|

14

|

0.1~0.25

|

45~3000 |

|

32

|

1-1/4

|

42.4

|

1.5*2

|

2*3

|

16

|

0.1~0.25

|

45~3000 |

|

40

|

1-1/2

|

48.3

|

1.5*2

|

2*3

|

16

|

0.1~0.25

|

45~3000 |

|

50

|

2

|

60.3

|

1.5*2

|

2*3

|

18

|

0.1~0.5

|

45~3000 |

|

65

|

2-1/23

|

76.1

|

1.5*2

|

2*3

|

20

|

0.1~0.5

|

45~3000 |

|

80

|

3

|

88.9

|

1.8*2.5

|

2*3

|

24

|

0.1~0.5

|

1000~6000 |

|

100

|

4

|

114.3

|

1.8*2.5

|

2*3

|

30

|

0.5~2

|

1000~6000 |

|

125

|

5

|

139.7

|

2.3*2.7

|

2*3

|

36

|

0.5~2

|

1000~6000 |

|

150

|

6

|

168.3

|

2.3*2.7

|

3*5

|

44

|

0.5~2

|

1000~6000 |

|

200

|

8

|

219.1

|

3.3*3.5

|

3*4.7

|

56

|

0.5~2

|

1000~6000 |

|

250

|

10

|

273

|

3.3*3.5

|

4*6

|

66

|

0.5~2

|

1000~6000 |

|

300

|

12

|

323.9

|

3.3*4.7

|

4*6

|

72

|

0.5~2

|

1000~6000 |

|

350

|

14

|

355.6

|

3.7*5

|

4*6

|

80

|

0.5~2

|

1000~6000 |

|

400

|

16

|

406.4

|

1.5*2

|

2*3

|

94

|

0.1*2

|

1000~6000 |

|

450

|

18

|

457

|

2*3

|

4*5

|

112

|

0.1*2

|

500~400 |

|

500

|

20

|

508

|

2*3

|

4*5

|

124

|

0.1*2

|

500~400 |

|

550

|

22

|

559

|

2*3

|

4*5

|

140

|

0.1*2

|

500~400 |

|

600

|

24

|

610

|

2*3

|

4*5

|

156

|

0.1*2

|

500~400 |

|

Siot:0.1mm~2mm Tolerance:0.05 |

|||||||

Packaging and Transportation of stainless steel All-welded wire-wrapped screen: