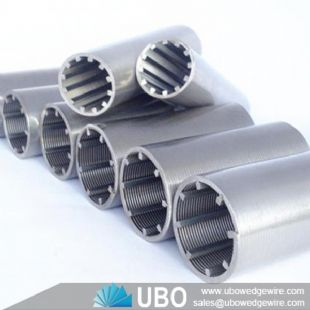

pulping equipment screen basket for pressure screen

| Category: | Wedge Wire Application |

|---|---|

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | Wedge Wire Cylinder |

| Application: | food processing, waste water filtration, pulp and paper as well as mineral processing applications |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of pulping equipment screen basket for pressure screen

Stainless steel wire screen have flat type, cylinder type, slope type and basket type. So Wedge wire screen is called as flat welded screen panel, cylinder wedge screen and sieve bend screen.

Wedge wire screen are producing by profile wire and support rods with the materials of galvanized steel, stainless steel and low carbon steel.

Applications for pulping equipment screen basket for pressure screen:

The stainless steel cylinders can be used in food processing, waste water filtration, pulp and paper as well as mineral processing applications. Wedge wire or profile screen half cylinders can be added to an auger or screw press to separate solids from liquids in food, waste water, minerals and industrial grit/chips from coolant.

Advantages for pulping equipment screen basket for pressure screen:

1) Many wing pieces, no winding, highly efficient rotary drum type rotor.

2) Pulp consistency can reach 2.5~4%, reduce water consumption and fiber loss of production process.

3) Heavy impurity discharge tube, ensure the security of the sieve drum operation.

4) Advanced structure, strong and durable, easy dismounting, low energy consumption, less wastage fiber.

5) Equipped with automatic oiling and mechanical seal water monitoring device, high degree of automation.

6) Compact structure, small power, high output.

7)1 year warranty and best after-sale service

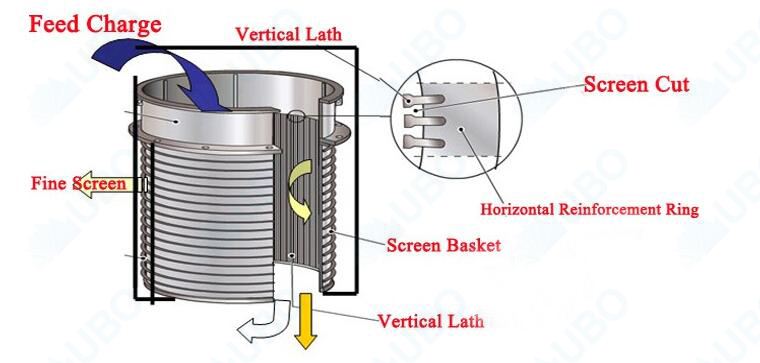

Working Principle for pulping equipment screen basket for pressure screen:

Pressure screen under the rotating function of drum sieve and rotating cylinder and centrifugation effect. The machine will separate the qualified pulp and non-qualified pulp.It consist of cylinder, cylinder cover, sieve drum, rotary cylinder,base and transmission parts, etc.

Specifications of pulping equipment screen basket for pressure screen:

|

Model NO. |

Screen Area (m2) |

Sieve hole size (mm) |

Seam Size (mm) |

Screen Hole (T/D) |

Screen Slot (T/D) |

Inlet pulp consistency (%) |

Motor Power (Kw) |

|

ZNS0.3 |

0.3 |

Φ1.6-Φ3.5 |

0.1-0.55 |

50-80 |

30-50 |

1-4 |

22-55 |

|

ZNS0.6 |

0.6 |

Φ1.6-Φ3.5 |

0.1-0.55 |

90-160 |

60-100 |

1-4 |

30-75 |

|

ZNS0.9 |

0.9 |

Φ1.6-Φ3.5 |

0.1-0.55 |

135-250 |

90-150 |

1-4 |

37-90 |

|

ZNS1.2 |

1.2 |

Φ1.6-Φ3.5 |

0.1-0.55 |

180-320 |

120-190 |

1-4 |

45-110 |

|

ZNS1.5 |

1.5 |

Φ1.6-Φ3.5 |

0.1-0.55 |

200-380 |

140-230 |

1-4 |

55-132 |

|

ZNS2 |

2 |

Φ1.6-Φ3.5 |

0.1-0.55 |

260-500 |

220-300 |

1-4 |

75-160 |

|

ZNS3 |

3 |

Φ1.6-Φ3.5 |

0.1-0.55 |

400-700 |

300-450 |

1-4 |

90-220 |

|

ZNS4 |

4 |

Φ1.6-Φ3.5 |

0.1-0.55 |

500-1000 |

350-730 |

1-4 |

132-280 |

Packaging and Transportation of pulping equipment screen basket for pressure screen: