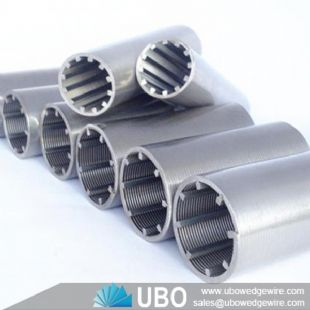

Welded Wedge curved screen cylinder

| Category: | Wedge Wire Application |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | Wedge Wire Cylinder |

| Application: | filters, strainers, architectural screens, water treatment underdrains, media support grids and overlays, infiltration gallery screens |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of Welded Wedge curved screen cylinder

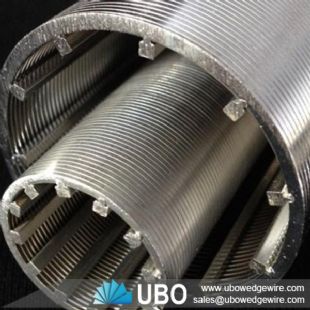

Water well screens are very effective in wells of this type since they can be manufactured with very small slot size and yet still maintain the necessary open area to minimize friction head loss. Most continuous wire wrap screen is manufactured from stainless steel rather than carbon steel in order to avoid problems which often leads to accelerated corrosion.

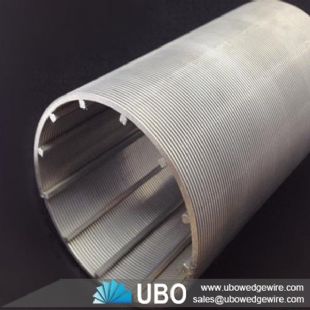

Applications for Welded Wedge Curved Screen Cylinder:

Application in deep well pump to dive the water pump, in the water-treating equipment, the environmental protection, the sea water transforms into the industrial water and life use water desalination treatment, running water treatment, water softening treatment; the petroleum industry, the petroleum product terminal filters; and the chemical acid, the alkali liquid filters, the ethyl alcohol and the organic solution recycling filters.

Advantage for Welded Wedge Curved Screen Cylinder:

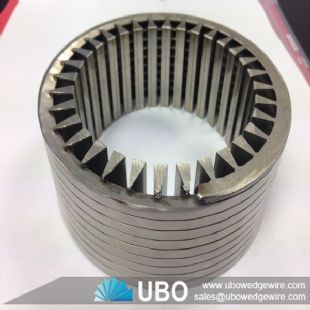

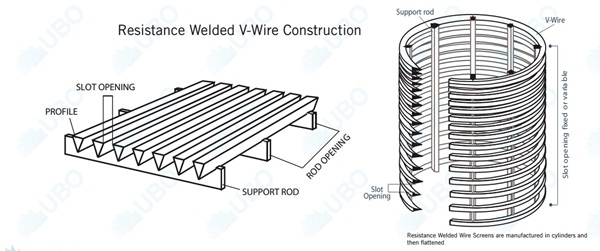

1) Non-clogging construction: The V-shape section plane of wedge wire screens (Wedge Wire type screens) creates the continuous slot, which can avoid blockage and make sure of the unimpeded water.

2) Large Filtering Area: The consecutive slot of wedge wire screens (Wedge Wire type screens) have wider open area,

and it can reduce the speed of the water entering to avoid the sand entering the screen under the great pressure, so it can control sand better, which can increase the water yield and prolong service time of the well.

3) Long service life Wire and support rods are all-welded, which makes wedge wire screens (Wedge Wire types screens) more robust and longer life.

4) Excellent construction strength: The longitudinal support rods and the continuous slot make the wedge wire screens(Wedge Wire type screens) have more excellent pressure-resistant performance.

5) Specifications and end connections of wedge wire screens(Wedge Wire screens) can me fabricated according to customers’ requirements.

Specifications of Welded Wedge curved screen cylinder:

|

wedge wire |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 |

|

support rod |

Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

|

Note: other specifications available as per request |

|

|

Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material |

galvanized low carton (LCG), stainless steel (304,316 etc.) |

|

Length |

up to 6 meters |

|

Diameter |

from 25mm to 1200mm. |

Packaging and Transportation of Welded Wedge curved screen cylinder: