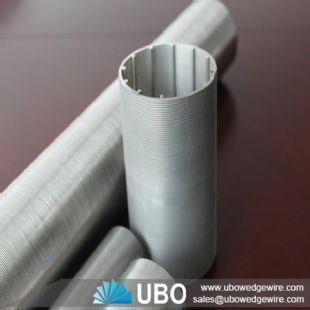

mining rotary drum sieve for industrial water

| Category: | Wedge Wire Application |

|---|---|

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | drum sieve |

| Application: | ferrous metals including hematite & magnetite And nonferrous metals including Lead, Zinc, Gold and Silver etc. |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of mining rotary drum sieve for industrial water

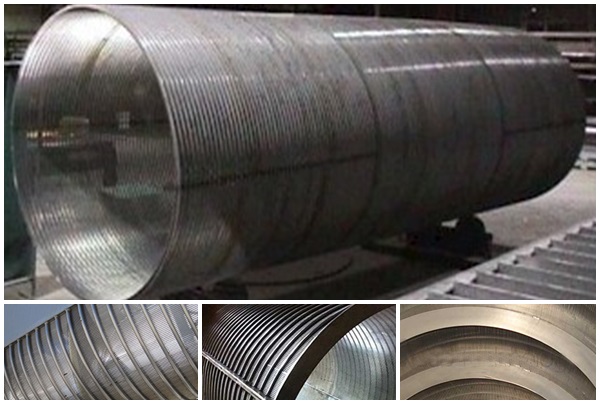

Mining rotary drum sieves are frequently employed for the purpose of separating substantial quantities of solids from liquids. The size of the particles permitted to pass through the drum is determined by the aperture of the screen. This process involves pumping slurry into one end of the drum, and as it rotates, smaller particles descend while larger ones gradually move towards the other end. Typically, these drums are set up at a slight incline to facilitate material flow.

Applications for mining rotary drum sieve for industrial water:

The Wedge Wire Rotary Drum Screen is commonly utilized in the processing of minerals, including ferrous metals like hematite and magnetite, as well as nonferrous metals such as lead, zinc, gold, and silver. It finds application in various industries:

Quarry: Ideal for screening and classifying materials like gravel, clay, mountain meal, sand, etc.

Coal Industry: Suitable for screening and classifying lump coal, coal dust, coal washing products.

Chemical and Mineral-selecting Industry: Appropriate for grading and classifying lumps or powdered substances. Moreover, it is also used in metallurgical processes, construction projects,and other related industries.

Features for rotary drum screen for industrial water:

1) Drum screen mesh is not easy to jam.

2) Smooth operation, low noise.

3) Simple structure, convenient maintenance.

4) Sieve tube can be closed, airtight dust easily.

5) The whole machine has high reliability, one-time investment is less.

6) Adopts special mesh, high screening efficiency, long service life.

Working Principle for mining rotary drum sieve for industrial water:

Pressure screen under the rotating function of drum sieve and rotating cylinder and centrifugation effect. The machine will separate the qualified pulp and non-qualified pulp.It consist of cylinder, cylinder cover, sieve drum, rotary cylinder,base and transmission parts, etc.

Specifications of mining rotary drum sieve for industrial water:

|

Specification (wedge wire):

|

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70

Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00

|

|

Specification (support rod):

|

Width(mm): 2.30 3.00 3.30 3.70

Height(mm): 2.70 3.60 4.70 5.60 6.30

Round: From 2.50mm to 6.0mm

|

|

Note: other specifications available as per request

|

|

|

Slot size

|

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request.

|

|

Material:

|

galvanized low carton (LCG), stainless steel (304,316 etc.)

|

|

Length

|

up to 6 meters.

|

|

Diameter

|

from 25mm to 1200mm.

|

|

End connection

|

Plain beveled ends, flanged or threaded couplings

|

Packaging and Transportation of mining rotary drum sieve for industrial water:

Each product is packed with bubble bag and then few bags to a wooden case (fumigation certificate)