Weld Wire Wrap Wedge Wire Screen for Water Process

| Category: | Wedge Wire Application |

|---|---|

| Material: | stainless steel |

| Properties: | wedge wire screen |

| Application: | water filtration,oil filtration,industry filtration |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of Weld Wire Wrap Wedge Wire Screen for Water Process

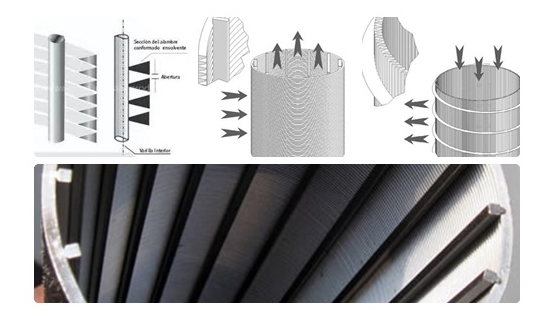

Welded wire wrap Wedge Wire screen is made up of rods and warp. The rod can be round wire, triangular wire or trapezoid wire. The warp is triangular wire (V-shaped wire).

China weld wire wrap Wedge Wire screen products was originally developed to overcome problems associated with cable tool wells drilled in fine grained, uniform sands in the North Central United States. These wells were typically completed in relatively shallow, thin aquifers that were very prolific in terms of water production. Continuous wire wrap screen are very effective in wells of this type since they can be manufactured with very small slot size and yet still maintain the necessary open area to minimize frictional head loss.

Continuous slot wire wrapped screen is manufactured by wrapping a shaped wire around an internal array of longitudinal rods and are joined by resistance welding. Screen sections are usually twenty feet long. Most continuous wire wrap screen is manufactured from stainless steel rather than carbon steel in order to avoid problems which often lead to accelerated corrosion.

productive process

No form closure connection that would allow vibration of the profiled bars

Automated welding process for high-precision manufacturing

Perfectly adjusted screen basket profiles

Available for all screens

Surface finishing as required

Features of Weld Wire Wrap Wedge Wire Screen for Water Process

1) It has high mechanical strength, can bear large pressure drop.

2) The wedge type slot can improve backflushing and regeneration performance.

3) Resistance to pressure, temperature, aging, corrosion, uedes in kinds of fluid.

4) Equal slots for filtering, can form equally distributed filter cake, easy to clean for reuse.

Application of Weld Wire Wrap Wedge Wire Screen for Water Process

Wedge wire screen is widely used in mining, coal, petroleum, fertilizer, grain, salt industry, environment protection, etc. Sieving liquid, powder and other materials.Petroleum, chemical industry, metallurgy, mining, pharmaceutical purification, drilling liquid purification and other industries use.

Specifications of Weld Wire Wrap Wedge Wire Screen for Water Process:

| Wedge wire |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 |

| Support rod |

Width(mm): 2.30 3.00 3.30 3.70 |

| Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

| Material |

galvanized low carton (LCG), stainless steel (304,316 etc.) |

| Length | up to 6m |

| Diameter | from 25mm to 1200mm. |

| End connection |

Plain beveled ends, flanged or threaded couplings |

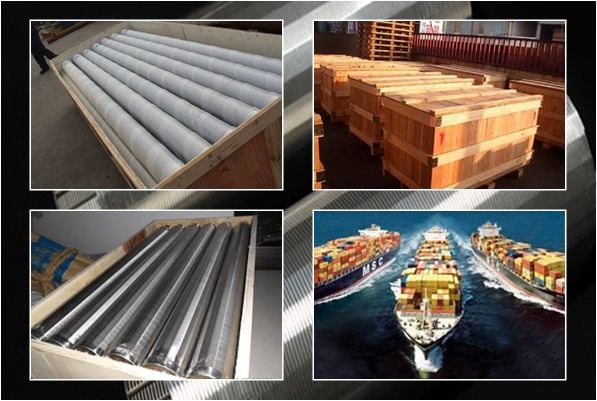

Packaging and Transportation of Weld Wire Wrap Wedge Wire Screen for Water Process: