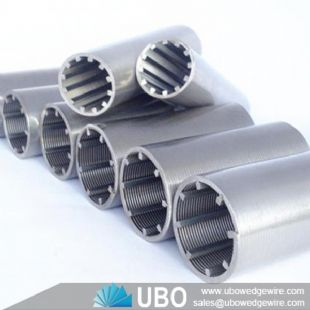

Wedge Wire Screen for Paper and Pulp

| Category: | Wedge Wire Application |

|---|---|

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | Wedge Wire Pipe |

| Application: | waste water filtration, pulp and paper as well as mineral processing applications. Wedge wire or profile screen half cylinders can be added to an aug |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of Wedge Wire Screen for Paper and Pulp

Wedge wire screens are an essential component in the paper and pulp industry. They are used in various stages of the paper and pulp production process, including screening, dewatering, and refining.

The screens are designed to withstand high temperatures, pressures, and corrosive environments, making them ideal for use in the paper and pulp industry.

Advantages for Wedge Wire Screen for Paper and Pulp:

The benefits of using wedge wire screens in the paper and pulp industry are numerous. They are durable, corrosion-resistant, and can withstand high temperatures and pressures. They also have a high open area, which allows for the efficient separation of solids and liquids. Additionally, they are easy to clean and maintain, which reduces downtime and increases productivity.

Applications for Wedge Wire Screen for Paper and Pulp:

One of the primary uses of wedge wire screens in the paper and pulp industry is in the screening process. During the screening process, the pulp is passed through a series of screens to remove impurities and separate the fibers. Wedge wire screens are used in this process because they have a high open area, which allows for the efficient removal of impurities while retaining the fibers.

Wedge wire screens are also used in the dewatering process. After the pulp has been screened, it is sent to a dewatering machine to remove excess water. Wedge wire screens are used in this process because they have a high flow rate and can withstand the high pressures required for dewatering.

In addition to screening and dewatering, wedge wire screens are also used in the refining process. During the refining process, the pulp is passed through a series of screens to break down the fibers and improve the quality of the paper. Wedge wire screens are used in this process because they have a high open area, which allows for the efficient removal of impurities while retaining the fibers.

Features for Wedge Wire Screen for Paper and Pulp:

Reducing the total cost of screening

We have the experience and the products to attack the major cost factors helping you reduce the total cost of screening without sacrificing reliability or performance.

Reducing energy

Improving capacity

Reducing wire width increases the open area of the screen cylinder without reducing slot size.

Increasing efficiency

Both the wire width and profile shape can be optimized to improve efficiency, based upon the contaminant that is targeted for removal.

Specifications of Wedge Wire Screen for Paper and Pulp:

|

Specification (wedge wire): |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

|

Specification (support rod): |

Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

|

Note: other specifications available as per request |

|

|

Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material: |

galvanized low carton (LCG), stainless steel (304,316 etc.) |

|

Length |

up to 6 meters. |

|

Diameter |

from 25mm to 1200mm. |

|

End connection |

Plain beveled ends, flanged or threaded couplings |

Packaging and Transportation of Wedge Wire Screen for Paper and Pulp: