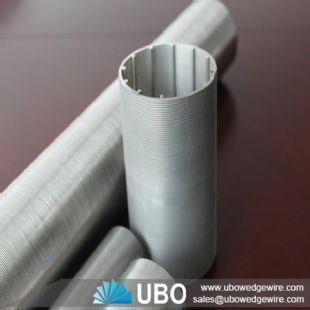

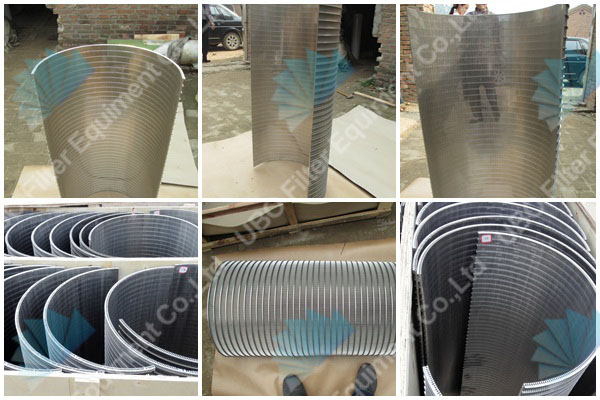

Stainless steel v wire curve screen plate for filtration

| Category: | Wedge Wire Application |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | wedge wire screen |

| Application: | water treatment, oilfield, mining, food industry, chemical industry, papermaking industry, decoration. |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of Stainless steel v wire curve screen plate for filtration

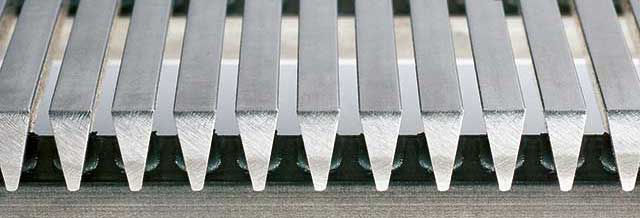

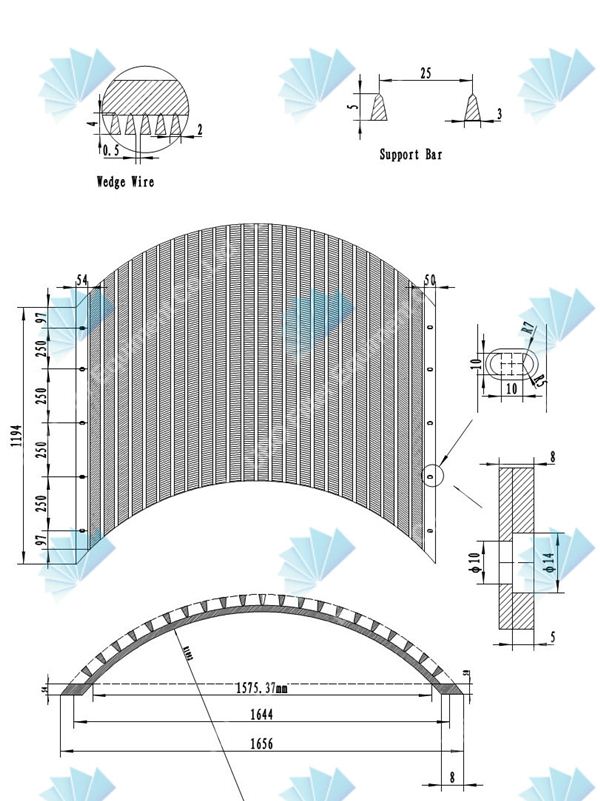

Stainless steel v wire curve screen plate, also called wedge wire sieve bend screens, wedge wire side hill screen panels are manufactured with stainless steel surface profiles and support profiles. The surface profile are welded onto support profiles at each intersection in a 120 degree.

The surface profile is commonly triangle wire, and the support profile can be triangle wire, wedge wire, round bar and rectangular bar. They can suit different machines and can be used in various applications. Support types of wedge wire screen panels Triangle wire. Round bar. Rectangular bar. Wedge wire. If there is any need please contact us via *wire-screen.com.

Advantages of Stainless steel v wire curve screen plate for filtration

Non-clogging surfaceLarge open area

Low pressure drop

Hydraulic efficiency

High flow rates

Mechanical strength

Abrasion-resistant

Easy cleaning

Uses of Stainless steel v wire curve screen plate for filtration

Mineral processing

Sewerage treatment

Quartz sand industry

Features of Stainless steel v wire curve screen plate for filtration

It uses eccentric block to produce strong exciting force.

Crossbeam and the main body of the screen are connected with high strength screw bolts. So they have the features of simple structure and easy maintenance.

It adopts tire coupling with capability of flexible connection and stable operation.

It adopts the structure of small amplitude, high frequency, large obliquity to make the screen hold the capability of high efficiency, large handling capacity, long life span, low consumption, little noise.

Specifications of Stainless steel v wire curve screen plate for filtration:

| Type | Screen Spec .mm | Layers | Sieve Pore mm | Max. Feed Size mm | Capacity t/h | Power KW | Vibrating Frequency HZ |

| YA1230 | 1200×3000 | 1 | 3-50 | 200 | 7.5-70 | 5.5 | 800-970 |

| 2YA1230 | 1200×3000 | 2 | 3-50 | 200 | 7.5-80 | 5.5 | 800-970 |

| 2YA1230 | 1200×3000 | 3 | 3-50 | 200 | 7.5-80 | 7.5 | 800-970 |

| YA1237 | 1200×3700 | 1 | 3-50 | 200 | 7.5-70 | 5.5 | 800-970 |

| 2YA1237 | 1200×3700 | 2 | 3-50 | 200 | 7.5-80 | 5.5 | 800-970 |

| 3YA1237 | 1200×3700 | 3 | 3-50 | 200 | 7.5-80 | 7.5 | 800-970 |

| 2YA1548 | 1500×4200 | 2 | 5-50 | 400 | 50-208 | 15 | 970 |

| 3YA1548 | 1500×4800 | 3 | 5-50 | 400 | 50-250 | 15 | 970 |

| 3YA1848 | 1800×4800 | 3 | 5-80 | 400 | 50-300 | 18.5 | 970 |

| 3YA1860 | 1800×6000 | 3 | 5-80 | 400 | 50-350 | 22 | 970 |

| 3YA2160 | 2100×6000 | 3 | 5-100 | 400 | 100-500 | 30 | 730 |

| 2YA2460 | 2400×6000 | 2 | 5-150 | 400 | 150-700 | 30 |

730 |

Packaging and Transportation of Stainless steel v wire curve screen plate for filtration: