Micron seam stainless steel V Wire Water Well Screen Mining wedge wire Screen

| Category: | Wedge Wire Application |

|---|---|

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | Wedge Wire Pipe |

| Application: | water treatment, water softhening, conversion of sea water into fresh water, the filter of food chemistry |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of Micron seam stainless steel V Wire Water Well Screen Mining wedge wire Screen

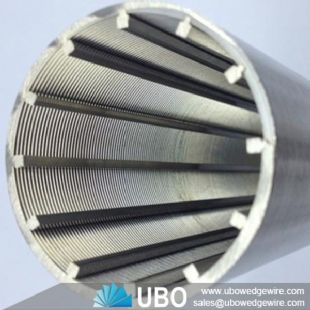

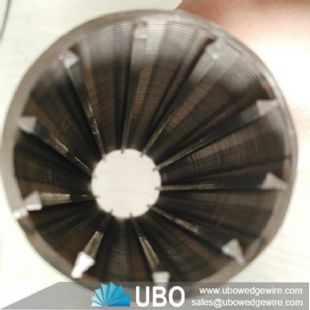

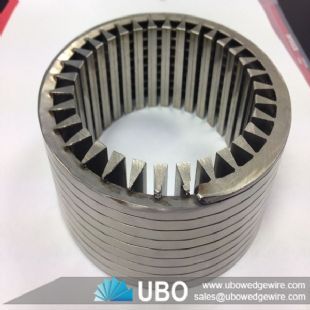

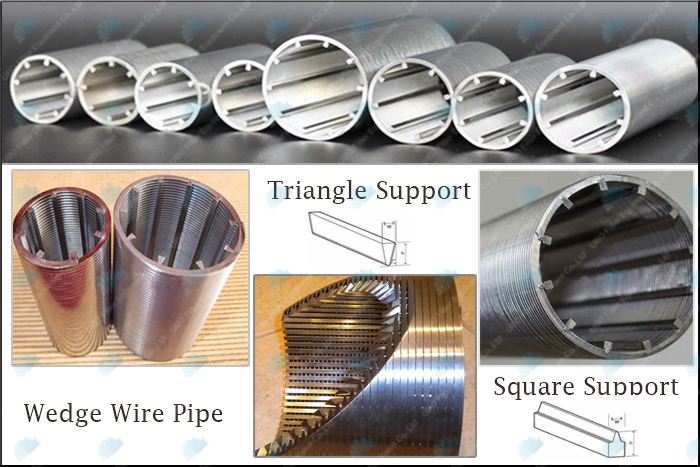

Micron seam stainless steel mining wedge wire screens are an essential component in the mining industry. These screens are designed to withstand harsh conditions and provide efficient and effective screening of minerals and other materials.

Features for Micron seam stainless steel Screen Mining wedge wire Screen:

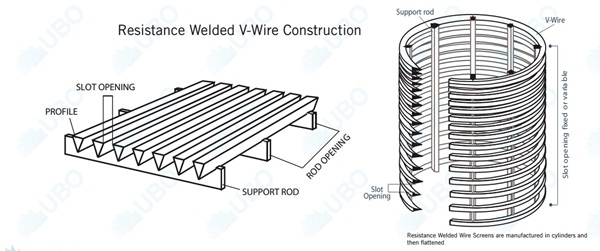

1) Vee wedge wire screens are considered the standard of the industry, combining proven performance with durability

2) Low-carbon, galvanized or stainless steel construction

3) Provide optimum well development and access to the aquifer

4) Large open area:.

5) Water enters at lower velocity, reducing screen surface erosion and encrustation

Characteristic for Micron seam stainless steel Screen Mining wedge wire Screen:

1. High Strength: Micron seam stainless steel mining wedge wire screens are made of high-quality stainless steel, which provides excellent strength and durability. These screens can withstand high pressure and heavy loads, making them ideal for use in the mining industry.

2. Corrosion Resistance: Stainless steel is highly resistant to corrosion, making it an ideal material for use in harsh environments. Micron seam stainless steel mining wedge wire screens are designed to resist corrosion, ensuring that they last longer and require less maintenance.

3. Precise Slot Openings: Micron seam stainless steel mining wedge wire screens are designed with precise slot openings, which allow for accurate and efficient screening of minerals and other materials. The slot openings can be customized to meet specific requirements, ensuring that the screens are suitable for a wide range of applications.

4. Easy to Clean: Micron seam stainless steel mining wedge wire screens are easy to clean, making them ideal for use in applications where cleanliness is essential. The screens can be cleaned using a variety of methods, including backwashing, air scouring, and chemical cleaning.

Technical parameter for Micron seam stainless steel Screen Mining wedge wire Screen:

The V-shaped wire can be made in different height and width to address various strength application, meanwhile, the spacing of individual slots can be varied during fabrication if geologic conditions require these variations in a screen's construction.

Specifications of Micron seam stainless steel V Wire Water Well Screen Mining wedge wire Screen:

|

Outside Diameter

|

Profile wire

|

Rod wire

|

Rod quantity

|

Slot size

|

Length

|

||

|

DN

|

Inch

|

mm

|

mm

|

mm

|

|

mm

|

mm

|

|

20

|

3/4

|

26.9

|

1.5*2

|

2*3

|

12

|

0.1~0.25

|

45~3000 |

|

25

|

1

|

33.7

|

1.5*2

|

2*3

|

14

|

0.1~0.25

|

45~3000 |

|

32

|

1-1/4

|

42.4

|

1.5*2

|

2*3

|

16

|

0.1~0.25

|

45~3000 |

|

40

|

1-1/2

|

48.3

|

1.5*2

|

2*3

|

16

|

0.1~0.25

|

45~3000 |

|

50

|

2

|

60.3

|

1.5*2

|

2*3

|

18

|

0.1~0.5

|

45~3000 |

|

65

|

2-1/23

|

76.1

|

1.5*2

|

2*3

|

20

|

0.1~0.5

|

45~3000 |

|

80

|

3

|

88.9

|

1.8*2.5

|

2*3

|

24

|

0.1~0.5

|

1000~6000 |

|

100

|

4

|

114.3

|

1.8*2.5

|

2*3

|

30

|

0.5~2

|

1000~6000 |

|

125

|

5

|

139.7

|

2.3*2.7

|

2*3

|

36

|

0.5~2

|

1000~6000 |

|

150

|

6

|

168.3

|

2.3*2.7

|

3*5

|

44

|

0.5~2

|

1000~6000 |

|

200

|

8

|

219.1

|

3.3*3.5

|

3*4.7

|

56

|

0.5~2

|

1000~6000 |

|

250

|

10

|

273

|

3.3*3.5

|

4*6

|

66

|

0.5~2

|

1000~6000 |

|

300

|

12

|

323.9

|

3.3*4.7

|

4*6

|

72

|

0.5~2

|

1000~6000 |

|

350

|

14

|

355.6

|

3.7*5

|

4*6

|

80

|

0.5~2

|

1000~6000 |

|

400

|

16

|

406.4

|

1.5*2

|

2*3

|

94

|

0.1*2

|

1000~6000 |

|

450

|

18

|

457

|

2*3

|

4*5

|

112

|

0.1*2

|

500~400 |

|

500

|

20

|

508

|

2*3

|

4*5

|

124

|

0.1*2

|

500~400 |

|

550

|

22

|

559

|

2*3

|

4*5

|

140

|

0.1*2

|

500~400 |

|

600

|

24

|

610

|

2*3

|

4*5

|

156

|

0.1*2

|

500~400 |

|

Siot:0.1mm~2mm Tolerance:0.05 |

|||||||

Packaging and Transportation of Micron seam stainless steel V Wire Water Well Screen Mining wedge wire Screen: