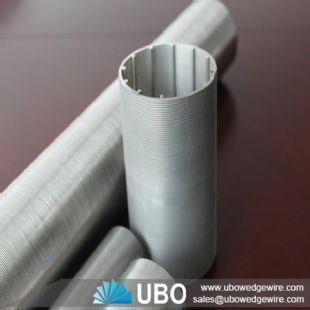

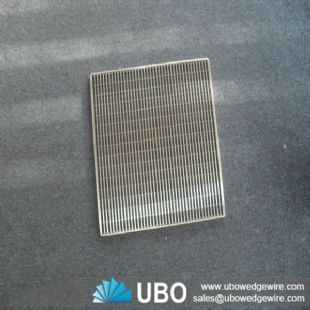

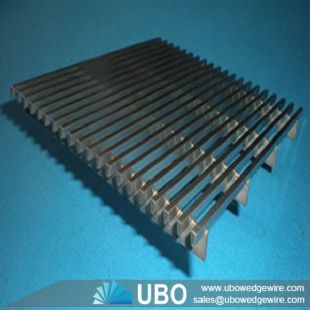

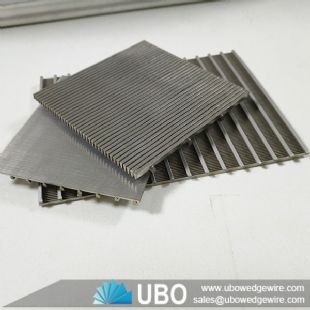

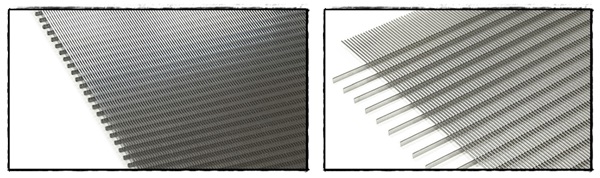

Flat screen grids with horizontal position welding

| Category: | Wedge Wire Application |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | wedge wire screen |

| Application: | various plants such as electric power, petroleum, chemical industry, metallurgy industry, machinery industry |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of Flat screen grids with horizontal position welding

Flat wedge wire screen panel is weave by Wedge Wire, it mainly used in liquid filter and solid seperate. It application in water treatment filed , mine coal industry, chemical industry etc.

Application for Flat screen grids with horizontal position welding:

1) Steel gratings trench cover is widely used by various plants such as electric power, petroleum, chemical industry, metallurgy industry, machinery industry.

2) Steel gratings trench cover is also widely used in shipbuilding, harbor, oceanographic engineering, building, paper mills, cement plant, medicine, spinning and weaving.

3) Steel gratings trench cover is applied in food stuff factory, transportation, municipal administration, parking lot, etc.

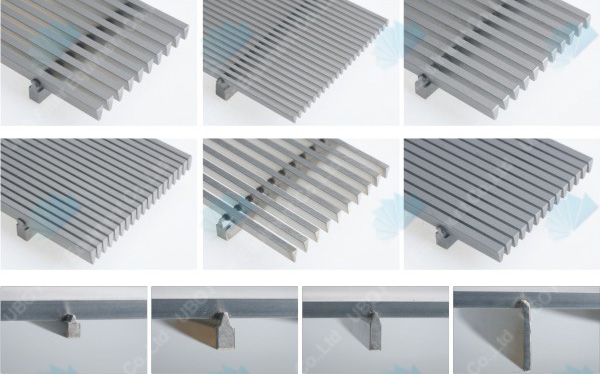

Features for Flat screen grids with horizontal position welding:

The welded stainless steel water well screen is made up of rods and warp. The rod can be round wire, triangular wire or trapezoid wire. The warp is triangular wire (V-shaped wire). Water well screens have a structure and high open area, as well as accurate slot dimension. At the same time, water well screen have heat-resisting, anti-corrosive, good machine capability, last long, safety and reliability and so on characteristics. It can be used in many kinds of medium filtering.

Advantage for Flat screen grids with horizontal position welding:

1) A continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone.

2) A Vshaped profile wire which avoids clogging and ensures an uninterrupted flow.

3) A uniform and efficient well development due to the continuous slot opening.

4) Ladder-like wire welded screens have a strong structure and high open area, as well as accurate slot dimension.

5) Ladder-like wire welded screens have the features of easy backwashing, last long, safety and reliability as well as low comprehensive cost.

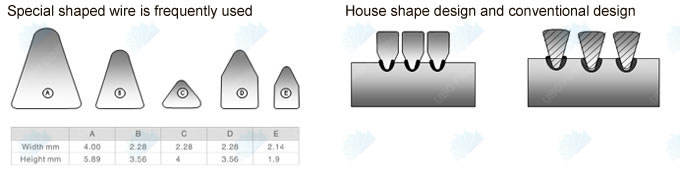

Specifications of Flat screen grids with horizontal position welding:

|

Surface Profile |

W

|

H

|

Material |

|

10S |

0.75

|

1.425

|

S304,S316L Hastelloy, Monel alloy of nickel and titanium, and other stainless steel |

|

11SL |

10.75

|

1.8

|

|

|

22S |

1.8

|

3.7

|

|

|

4S |

0.45

|

1.2

|

|

|

50SL |

3.4

|

7.5

|

|

Surface Profile

|

W

|

H

|

Material

|

|

Q22

|

2

|

2.28

|

S304,S316L Hastelloy, Monel alloy of nickel and titanium, and other stainless steel |

|

Q35

|

3

|

5

|

|

|

Q53

|

4

|

3

|

|

|

D56

|

4

|

5.6

|

|

|

D45

|

3.8

|

6.0

|

Packaging and Transportation of Flat screen grids with horizontal position welding: