Coal Wedge Wire Filter Sieve Bend Screen

| Category: | Wedge Wire Application |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | wedge wire screen |

| Application: | Sugar, Coal Mining & Quarrying, Mineral Processing, Cement, and Industrial & Urban Effluent Treatment etc |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of Coal Wedge Wire Filter Sieve Bend Screen

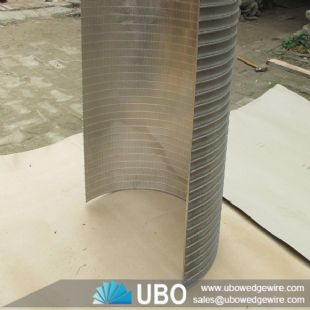

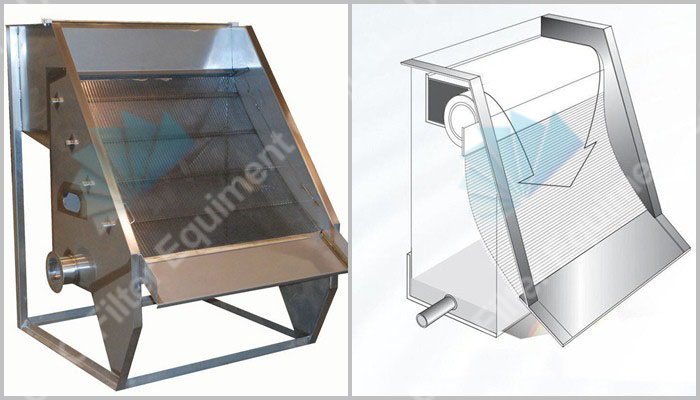

Coal Wedge Wire Filter Sieve Bend Screen also known as side hill screens, parabolic screens, run down screens, gravity screens and DSM screens.

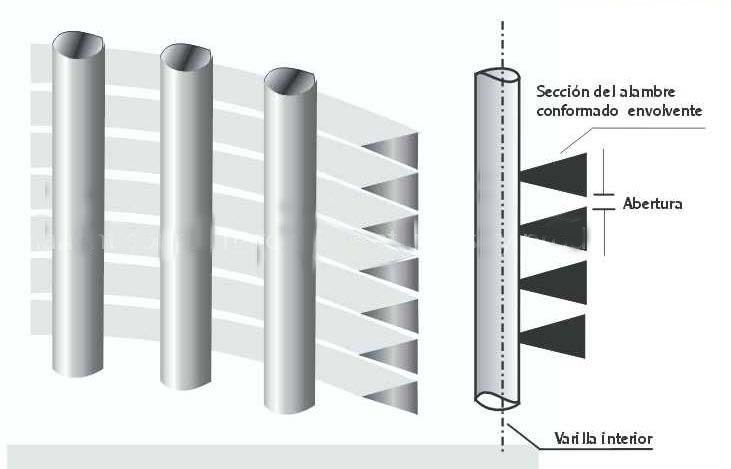

A sieve bend consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat wedge screen due to forces exerted as material flows against the curved surface.

Sieve Bends are cross-flow screens. The profile wires are slightly tilted so that the leading edge is position higher which greatly increases the dewatering capacity.

Applications of Coal Wedge Wire Filter Sieve Bend Screen

They are used in industries such as Sugar, Coal Mining & Quarrying, Mineral Processing, Cement, and Industrial & Urban Effluent Treatment etc. Sieve bend screens are also used as a pre-filter in urban & industrial waste treatment plants to improve the performance of the clarifier by drastically reducing the load. Widely used for fiber removal in Starch industry.

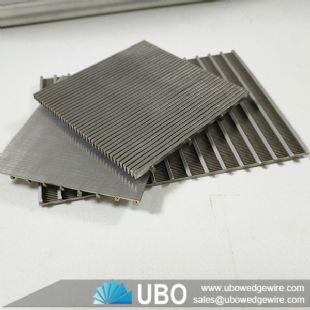

Features of Coal Wedge Wire Filter Sieve Bend Screen

-- Efficient separation with sharp cut;

-- Unique profile wire welded wege wire sieve bend;

-- Safe and stand equipment;

-- Simple screen replacement design;

-- Pneumatically operated washing jet for screen surface.

Specifications of Coal Wedge Wire Filter Sieve Bend Screen:

| Model | Effective Screen Width x Radius (mm) x Angle | Approx. Assembly Dimensions Width x Depth x Height (mm) | Approx. Mass of Assembly (kg) |

| JXR600 | 600 x 1018 x 45 | 786 x 900 x 1200 | 140 |

| JXR900 | 900 x 1018 x 45 | 1086 x 900 x 1200 | 180 |

| JXR1200 | 1200 x 1018 x 45 | 1386 x 900 x 1200 | 225 |

| JXR1500 | 1500 x 1018 x 45 | 1686 x 900 x 1200 | 265 |

| JXR900 | 900 x 2036 x 45 | 1086 x 1400 x 2100 | 325 |

| JXR1200 | 1200 x 2036 x 45 | 1386 x 1400 x 2100 | 395 |

| JXR1500 | 1500 x 2036 x 45 | 1686 x 1400 x 2100 | 455 |

| JXR1800 | 1800 x 2036 x 45 | 2040 x 1400 x 2100 | 755 |

| JXR2100 | 2100 x 2036 x 45 | 2340 x 1400 x 2100 | 835 |

| JXR2400 | 2400 x 2036 x 45 | 2640 x 1400 x 2100 | 920 |

| JXR2700 | 2700 x 2036 x 45 | 2990 x 1400 x 2100 | 1,035 |

| JXR3000 | 3000 x 2036 x 45 | 3290 x 1400 x 2100 | 1,120 |

Packaging and Transportation of Coal Wedge Wire Filter Sieve Bend Screen: