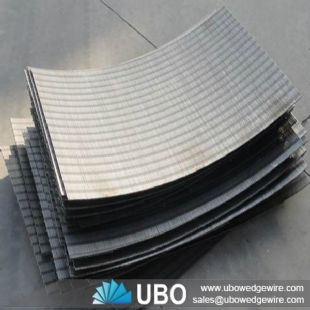

Wedge wire cross flow arc screen

| Category: | Sieve Bend Screen |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | wedge wire screen |

| Application: | water-treatment , water well drilling ,oil well drilling ,mineral processing, coal-cleaning plant |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

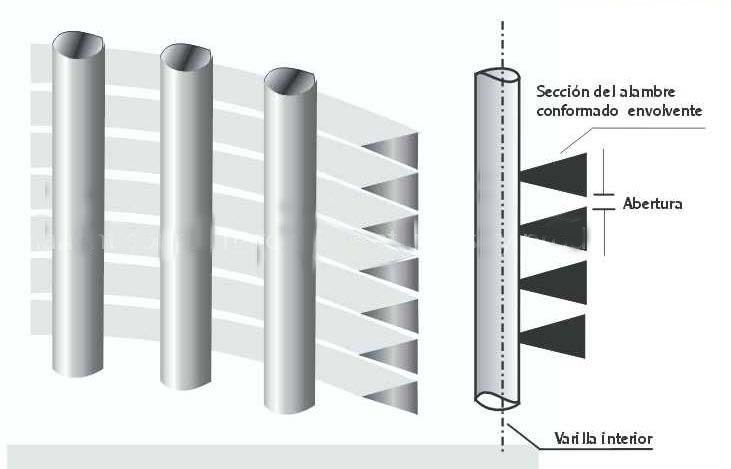

Details of Wedge wire cross flow arc screen

Wedge wire cross flow arc screen is a screen surface for the arc to open away from wet fine screening equipment. According to the different feeding methods are divided into gravity and pressure arc curved sieve screen. Artesian curved screen is a small curvature, low pressure, low-speed feeding curved screen, thanks to a certain height difference of the feed material screening and to the mouth, along the arc tangent in the direction screen surface for gravity feed. Pressure is a sweeping curved screen, high-pressure, high-speed feeding curved screen, which is the use of sand pump nozzle into the raw material to the slurry under the action of the material at high speed along the curved screen surface tangent to the direction of the pressure feedstock.

Usages of wedge wire curve screen

Widely used in mining, coal, petroleum, fertilizer, grain, salt, environmental protection and other industries. For sieving liquid, powder and other materials. In petroleum, chemical industry, metallurgy, mining, pharmaceutical purification and drilling liquid purification.

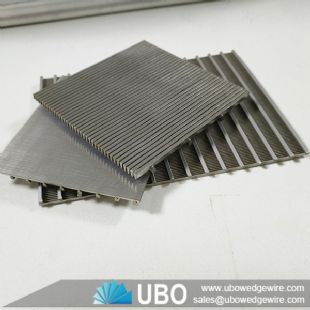

Advantages of Wedge wire cross flow arc screen

flatness to within tight tolerances

no weakening of the welds, because of flattening (and no stress corrosion problems as a result)

accurate distance between support profiles

possibility of different support wires in one screen

possibility of variable spacing between support wires in one screen

Specifications of Wedge wire cross flow arc screen:

| Model | Effective Screen Width x Radius (mm) x Angle | Approx. Assembly Dimensions Width x Depth x Height (mm) | Approx. Mass of Assembly (kg) |

| JXR600 | 600 x 1018 x 45 | 786 x 900 x 1200 | 140 |

| JXR900 | 900 x 1018 x 45 | 1086 x 900 x 1200 | 180 |

| JXR1200 | 1200 x 1018 x 45 | 1386 x 900 x 1200 | 225 |

| JXR1500 | 1500 x 1018 x 45 | 1686 x 900 x 1200 | 265 |

| JXR900 | 900 x 2036 x 45 | 1086 x 1400 x 2100 | 325 |

| JXR1200 | 1200 x 2036 x 45 | 1386 x 1400 x 2100 | 395 |

| JXR1500 | 1500 x 2036 x 45 | 1686 x 1400 x 2100 | 455 |

| JXR1800 | 1800 x 2036 x 45 | 2040 x 1400 x 2100 | 755 |

| JXR2100 | 2100 x 2036 x 45 | 2340 x 1400 x 2100 | 835 |

| JXR2400 | 2400 x 2036 x 45 | 2640 x 1400 x 2100 | 920 |

| JXR2700 | 2700 x 2036 x 45 | 2990 x 1400 x 2100 | 1,035 |

| JXR3000 | 3000 x 2036 x 45 | 3290 x 1400 x 2100 | 1,120 |

Packaging and Transportation of Wedge wire cross flow arc screen: