Mineral processing wedge wire welded cross flow sieves

| Category: | Sieve Bend Screen |

|---|---|

| Material: | Low carton, low carton galvanized steel (LCG),stainless steel (304,316etc.) |

| Properties: | sieve bend screen |

| Application: | the water-treating equipment, the environmental protection, the sea water transforms into the industrial water |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of Mineral processing wedge wire welded cross flow sieves

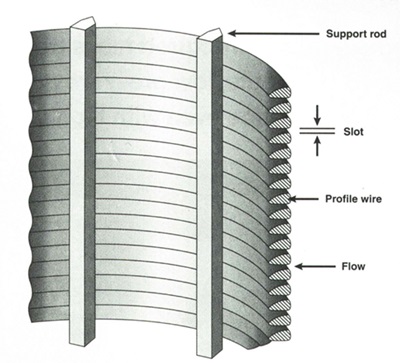

The profile wire stainless steel pipe screen is created by wrapping a profile wire cylindrical around longitudinal placed support rods. All wires and rods are resistance welded at each point of contact.

Details features for Mineral processing wedge wire welded cross flow sieves:

V-Shaped Slots: Openings shaped like a "v" that open toward the inside of the well tend to allow the particles that are just barely smaller than the width of the slot pass. In other shapes of openings, these particles would get caught in the screen and clog it.

Continuous Slots: The special design gives continuous slot opening across the periphery and length of screen.

Very Large % Open Area: This design gives continuous slot and hence the% open area for water to enter is more than 2 times that of conventional slotted pipes of any size and slot opening. This allows more water to enter at much lesser frictional head loss and the efficiency of tube well is improved appreciably.

Better Sand Filtration: Due to specialize manufacturing process, wide range of slot opening is available down to 0.15 mm to allow proper slot selection depending upon the size of sand in particular area. This gives better sand control and reduced pump maintenance and longer tube well life.

Energy Saving: Due to reduce frictional head losses and increased discharge, the pump load reduces the power required to pump same quantity of water. Power saving of around 20-25% is observed.

Uses for Mineral processing wedge wire welded cross flow sieves:

It can use with the deep well pump, dive the water pump, also may use in the water-treating equipment, the environmental protection, the sea water transforms into the industrial water and life use water desalination treatment, running water treatment, water softening treatment, the petroleum industry: The petroleum product terminal filters and the chemical acid, the alkali liquid filters, the ethyl alcohol and so on the organic solution recycling filters.

Characteristics for Mineral processing wedge wire welded cross flow sieves:

The welded stainless steel wire wrapped pipe screen is made up of rods and profile wire. The rod can be round wire, triangular wire or trapezoid wire. The profile wire is triangular wire (V-shaped wire). This type of pipe screen has a structure and high open area, as well as accurate slot dimension. At the same time, stainless steel pipe screen has heat-resisting, anti-corrosive, good machine capability, last long, safety and reliability and so on characteristics. It can be used in many kinds of medium filtering.

Specifications of Mineral processing wedge wire welded cross flow sieves:

|

V-Wire Wrap Water Well Screen

|

|

|

Material:

|

Low carton, low carton galvanized steel (LCG), steel treated with plastic spraying, stainless steel (304,316etc.)

|

|

Wedge Wire (mm):

|

Width : 1.50 1.80 2.30 3.00 3.30 3.70

|

|

Height : 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00

|

|

|

Support Rod (mm):

|

Width : 2.30 3.00 3.30 3.70

|

|

Height : 2.70 3.60 4.70 5.60 6.30

|

|

|

Round : 2.50mm -- 6.0mm

|

|

|

Diameter ranging

|

from 1 inch -----45 inch.

|

|

Length:

|

lengths up to 6 meters.

|

|

Slot size:

|

0.10, 0.15, 0.20, 0.25, 0.30,....., 3.00 also achieved upon request.

|

|

Note: Other specifications can be customized according to your requirement

|

|

Packaging and Transportation of Mineral processing wedge wire welded cross flow sieves: