Mineral processing wedge wire welded cross flow sieves

| Category: | Wedge Wire Application |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | wedge wire screen |

| Application: | water-treatment, water well drilling ,oil well drilling ,mineral processing, coal-cleaning plant |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of Mineral processing wedge wire welded cross flow sieves

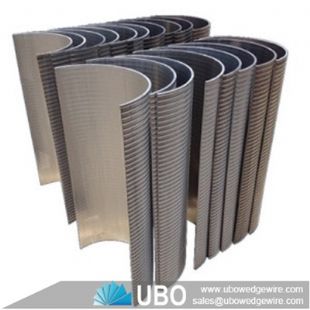

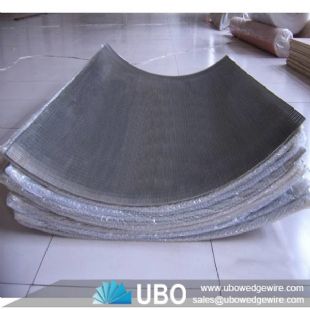

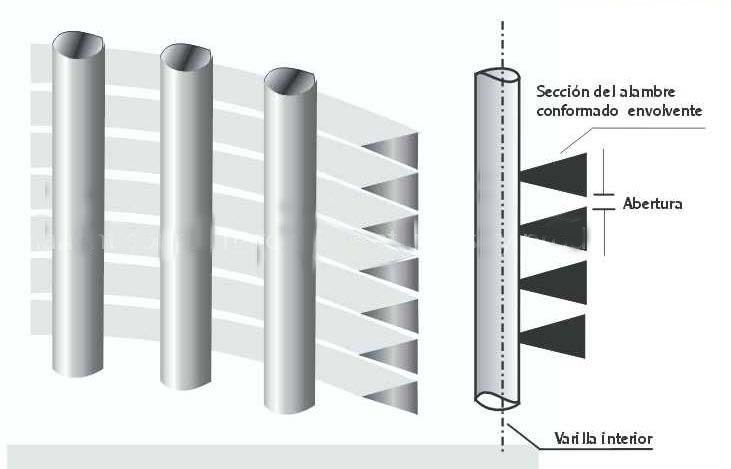

Mineral processing wedge wire welded cross flow sieves, also called wedge wire curve screens, wedge wire panels, are manufactured with stainless steel surface profiles and support profiles. The surface profile are welded onto support profiles at each intersection in a 90 degree.

Mineral processing wedge wire welded cross flow sieves are composed of surface profile and support profile. The surface profile is commonly triangle wire, and the support profile can be triangle wire, wedge wire, round bar and rectangular bar. They can suit different machines and can be used in various applications.

Features of Mineral processing wedge wire welded cross flow sieves

The benefit of wedge wire screen is more open area, have very precise openings ,maximum design flexibility, stronger and more durable, economical ,easier installation and long-term operating etc.

Applications of Mineral processing wedge wire welded cross flow sieves

wedge wire screen is widely used in filters, strainers, architectural screens, water treatment underdrains, media support grids and overlays, infiltration gallery screens, lauter tun screens,

many other liquids, solids separation applications.

Specifications of Mineral processing wedge wire welded cross flow sieves:

|

Model NO.

|

Screen Area

(m2)

|

Sieve hole size (mm)

|

Seam Size (mm)

|

Screen Hole (T/D)

|

Screen Slot (T/D)

|

Inlet pulp consistency (%)

|

Motor Power (Kw)

|

|

ZNS 0.3

|

0.3

|

Φ1.6~Φ3.5

|

0.1~0.55

|

50~80

|

30~50

|

1~4

|

22~55

|

|

ZNS 0.6

|

0.6

|

Φ1.6~Φ3.5

|

0.1~0.55

|

90~160

|

60~100

|

1~4

|

30~75

|

|

ZNS 0.9

|

0.9

|

Φ1.6~Φ3.5

|

0.1~0.55

|

135~250

|

90~150

|

1~4

|

37~90

|

|

ZNS 1.2

|

1.2

|

Φ1.6~Φ3.5

|

0.1~0.55

|

180~320

|

120~190

|

1~4

|

45~110

|

|

ZNS 1.5

|

1.5

|

Φ1.6~Φ3.5

|

0.1~0.55

|

200~380

|

140~230

|

1~4

|

55~132

|

|

ZNS 2

|

2

|

Φ1.6~Φ3.5

|

0.1~0.55

|

260~500

|

220~300

|

1~4

|

75~160

|

|

ZNS 3

|

3

|

Φ1.6~Φ3.5

|

0.1~0.55

|

400~700

|

300~450

|

1~4

|

90~22

|

|

|

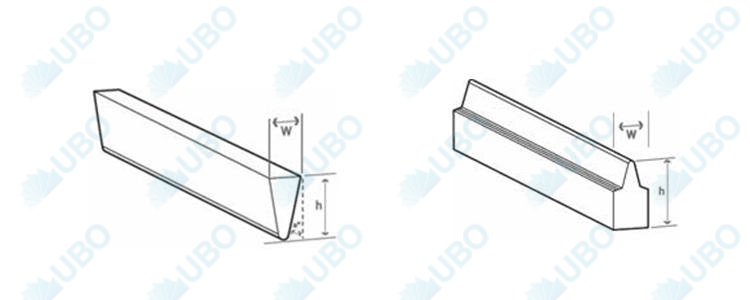

Wire Width |

Wire Height |

Relief Angle |

Typical Support Rods |

|

30V |

.030" |

.06" |

10 |

.125" round |

|

45V |

.045" |

.09" |

10 |

.125" round |

|

63V |

.063" |

.11" |

13 |

.156" round |

|

69U |

.069" |

.17" |

8 |

.075" x 1" bar |

|

93V |

.093" |

.15" |

13 |

.25" round or .075" bar |

|

93U |

.093" |

.17" |

5 |

.25" or .38" round |

|

125V |

.125" |

.20" |

13 |

.38" round |

Packaging and Transportation of Mineral processing wedge wire welded cross flow sieves: