What does a Static Run Down Screen Do

Advantages of Static Run Down Screen

-- very low running costs

-- ultra low maintenance

-- slurry throughput greater than 230m3/hour

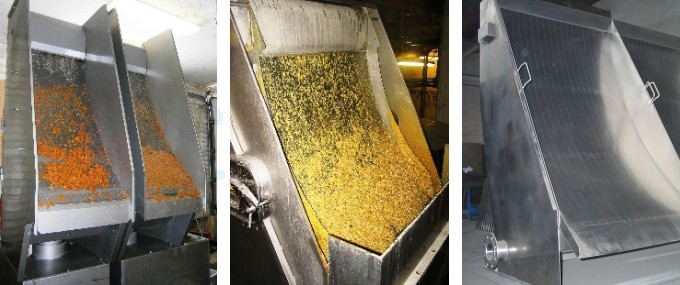

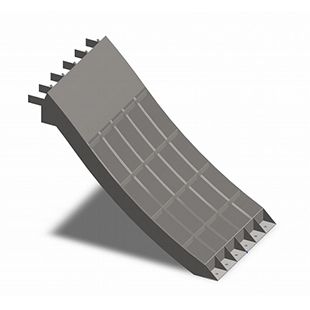

A no-moving part unit that cascades solid laden slurry down a wedge wire screen to separate solids from liquids. The slurry is pumped or gravity fed into the unit’s top chamber, flows over a full width weir and cascades down the curved screens surface.

Static and vibrating options, each with 6 capacities up to 250m3/hr The liquid passes through the screens voids into a collection chamber below. Solid particles larger than the screens void size stay on the surface, and as this accumulating mass increases in weight/volume, gently slides down the screens surface, compacted and further dewatered as it travels down. At the bottom discharge chute, the solids simply drop off or in some applications, go for further dewatering by a drum or screw press unit. The static screen version has it screen rigidly fixed in position whereas the other, more efficient unit, has its screen mounted to enable a small motor to vibrate it.

Options Available Solid particle removal for most applications with screen slot (void) sizes from 100 micron to 4mm Two unit types available: Static unit Fixed screen for general purpose use (void size 250 micro up to 4mm) Vibrating unit The screen gently vibrates for improve efficiency for higher throughput and smaller particle size removal (void size 100 micron up to 4mm) Automatic screen cleaning system (only required for specific slurries) Open or closed units (closed unit generally required for auto cleaning systems)

Application of Static Run Down Screen

1) Site indoor or outdoor

2) Satisfactory for most applications for high throughput, cost effective separation

3) Use as a pre-treatment to further dewatering separated solids with a Screw Press unit

4) Throughput determined by:

a. Unit type: Static or Vibrating b. Slurry Dry Matter, Viscosity and fow rate to unit c. Desired solid particle size removal d. Unit size

Materials / Construction 1. Generally supplied in Stainless Steel - Different materials can be supplied per application 2. Unit size and screen slot (void) size for most applications 3. 100% non-corrosive 4. Sits straight onto floor or elevated frame 5. No moving parts on static unit, minimal on vibrating unit