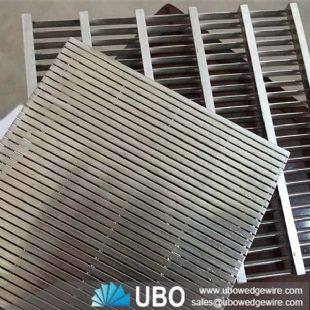

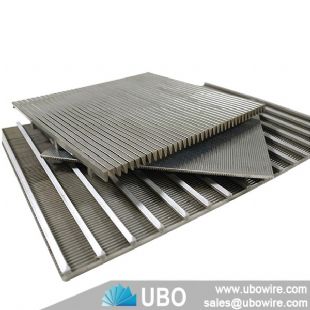

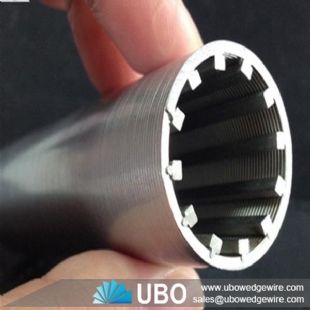

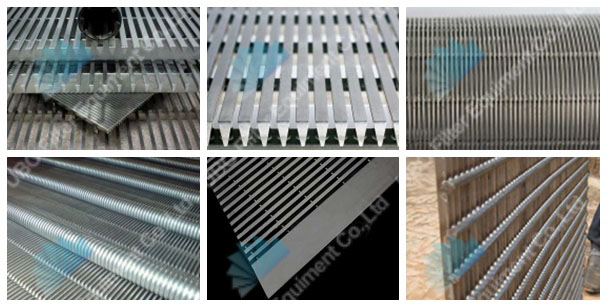

wire wrapped screen Wedge Wire v wire water well screen

| Category: | Wedge Wire Screen Panel |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | Wedge Wire Screen Panel |

| Application: | mining, coal, petroleum, chemical fertilizer, food, environmental protection and other industry to sew sieve net, oil filter, salt indu |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of wire wrapped screen Wedge Wire v wire water well screen

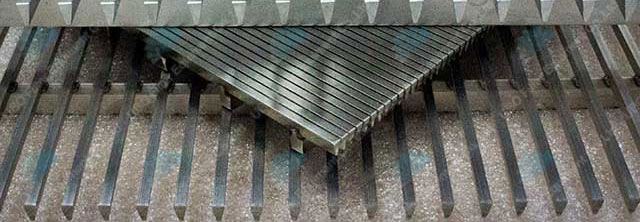

Flat screens are used in a wide variety of processes across several industry sectors. We use state-of-the-art manufacturing techniques that place our products at the cutting edge of wedge wire screen construction. Flat panels can be designed and manufactured according to customer specifications and come in a wide range of grades - from fine gap screens for small particle sizes to heavy duty screens for heavy load applications

Usages for wire wrapped screen Wedge Wire v wire water well screen:

1.) Widely used in vairous kinds of medium filtering

2.) As the fitting using in the water-treating equipment ( the environment protection; the sea water transforms into the industrial water and life use water desalination treatment; running water treatment; softening treatment;

3.) The petroleum industry: the petroleum product terminal filters and the chemical acid; the alkali liquid filters, the ethyl alcohol;

4.) The organic solution recycling filter

Features for wire wrapped screen Wedge Wire v wire water well screen:

Low Headroom - only 1.1 metres (44") tall for the 900 mm arc length unit.

Energy Efficient - operates with no moving parts and with no energy input.

Space Efficient - treats up to 122 litres per second per square metre of floor space.

Quiet Operation - no moving parts means no mechanical or electrical vibrations.

Accurate Sizing - can be used for sizing solid particles down to 0.2 mm (0.008").

Low Maintenance - the profile wire screen resists clogging by near-size particles, and the all-stainless steel construction ensures a long, corrosion-free installation.

Easy Screen Replacement - a typical screen can be replaced in 10 minutes with no tools.

Characteristic for wire wrapped screen Wedge Wire v wire water well screen:

1.) Wedge wire screen style isn't easy to be locked

2.) Due to the different pressure between inside from outside,it could be very easily to clean the plugging material.

3.) We are eager for long-terms cooperative parters ,our factory promise the best quality to have a high filtering accuracy, high strengh and durability

4.) We have the most advanced equipments and the most professional workers , so totally could be as per customer's drawing to produce new styles.

Specifications of wire wrapped screen Wedge Wire v wire water well screen:

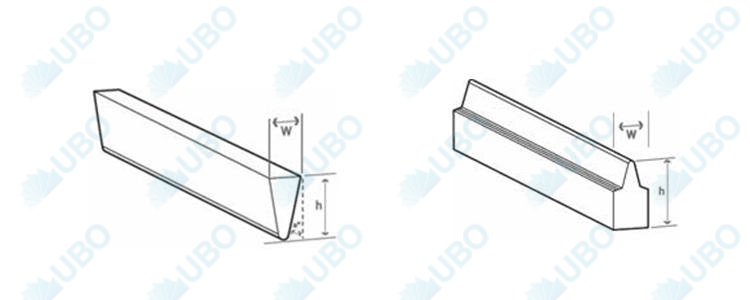

|

urface Profile |

W

|

H

|

Material |

|

10S |

0.75

|

1.425

|

S304,S316L Hastelloy, Monel alloy of nickel and titanium, and other stainless steel |

|

11SL |

10.75

|

1.8

|

|

|

22S |

1.8

|

3.7

|

|

|

4S |

0.45

|

1.2

|

|

|

50SL |

3.4

|

7.5

|

|

Surface Profile

|

W

|

H

|

Material

|

|

Q22

|

2

|

2.28

|

S304,S316L Hastelloy, Monel alloy of nickel and titanium, and other stainless steel |

|

Q35

|

3

|

5

|

|

|

Q53

|

4

|

3

|

|

|

D56

|

4

|

5.6

|

|

|

D45

|

3.8

|

6.0

|

Packaging and Transportation of wire wrapped screen Wedge Wire v wire water well screen: