wedge wire screen sieve bend screen supplier

| Category: | Wedge Wire Application |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | wedge wire screen |

| Application: | water treatment, oilfield, mining, food industry, chemical industry, papermaking industry, decoration. |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

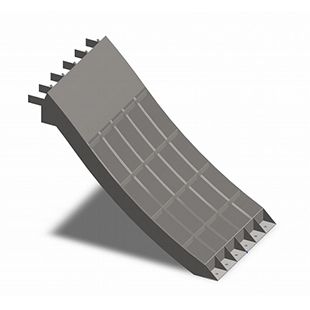

Details of wedge wire screen sieve bend screen supplier

Wedge wire screen sieve bend screen also known as side hill screens, parabolic screens,rundown screens, gravityscreens and DSM screens, can be custom designed to separate solids from liquids in various applications including food processing, pulp and paper, waste water cleanup, surface water intakes,corn wet milling, coal preparation, and gold recovery.Sieve Bends are cross-flow screens. The profile wires are slightly tilted so that the leading edge is position higher which greatly increases the dewatering capacity.A sieve bend consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat wedge screen due to forces exerted as material flows against the curved surface.

Applications of wedge wire screen sieve bend screen supplier

sieve bend screens are mainly used for liquid/solid seperation and manufactured to suit a wide range of industries such as Sugar, Coal Mining & Quarrying, Mineral Processing, Cement, and Industrial & Urban Effluent Treatment etc. Sieve bend screens are also used as a pre-filter in urban & industrial waste treatment plants to improve the performance of the clarifier by drastically reducing the load. Our sieve bends offer many advantages: more fine fibre removal ,better flow rate ,original solutions to reduce spare parts cost , special alloys for improved wear life ,customised surface finishing .

Advantages of wedge wire screen sieve bend screen supplier

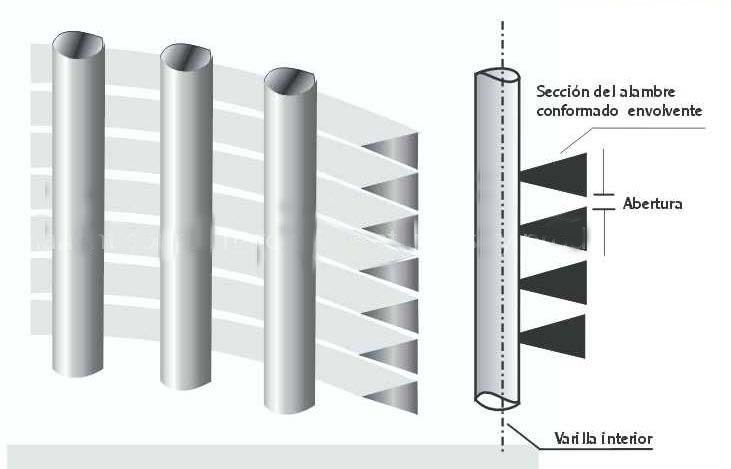

-- A continuous slot opening which significantly increases the available open area, thus providing a greater access to the water bearing zone.

-- A ‘V’ shaped profile wire which avoids clogging and ensures uninterrupted flow.

-- A uniform and efficient well development due to the continuous slot opening.

Specifications of wedge wire screen sieve bend screen supplier:

|

Specification (wedge wire):

|

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70

Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00

|

|

Specification (support rod):

|

Width(mm): 2.30 3.00 3.30 3.70

Height(mm): 2.70 3.60 4.70 5.60 6.30

Round: From 2.50mm to 6.0mm

|

|

Note: other specifications available as per request

|

|

|

Slot size

|

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request.

|

|

Material:

|

galvanized low carton (LCG), stainless steel (304,316 etc.)

|

|

Length

|

up to 6 meters.

|

|

Diameter

|

from 25mm to 1200mm.

|

|

End connection

|

Plain beveled ends, flanged or threaded couplings

|

| Profile Wire Width | Relief Angle | Typical Support Rod |

| 1/16” (.063”) | 13 degrees | Small round rod |

| 3/32” (.093”) | 13 degrees | Round or Rectangular bar |

| 1/8” (.125”) | 13 or 5 degrees |

Round or Rectangular bar |

Packaging and Transportation of wedge wire screen sieve bend screen supplier:

Each product is packed with bubble bag and then few bags to a wooden case (fumigation certificate)