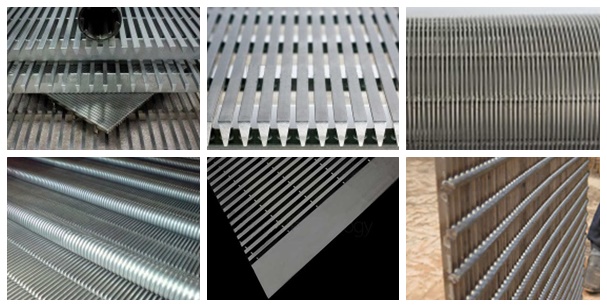

slotted filter v shaped wedge wire screen flat screen

| Category: | Wedge Wire Application |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | Wedge wire screen |

| Application: | sugar juice filtration, waste water treatment, crude oil and natural gas production and vessel internals solving problems of solid |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

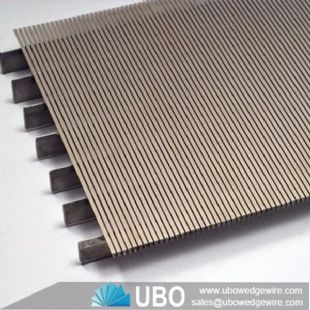

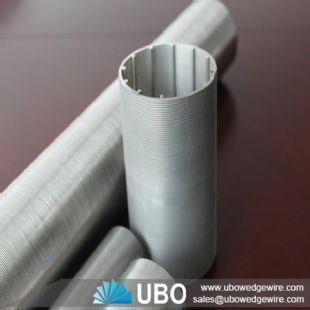

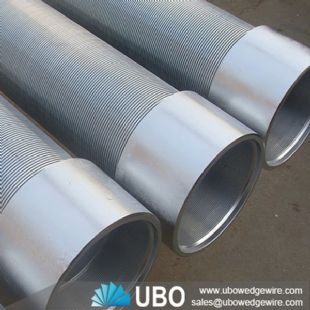

Details of slotted filter v shaped wedge wire screen flat screen

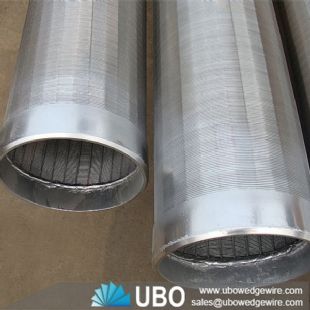

wedge wire screen panel for screen screening is a screen formed by welding a wire and a support rod, and the shape of the wire is a V-shaped wire, and the shape of the support rod may be V Wire or square wire or round wire. There is a certain gap between the screen line and the screen line. The value of the gap is provided by the customer or the manufacturer can recommend it based on the size and viscosity of the particular filter object. The gap of the screen is V-shaped, the welding point is firm, it is not easy to block, the flowability is good, the permeability is good, and it is widely used in the fields of coal washing, screening, filtration and the like.

Applications for slotted filter v shaped wedge wire screen flat screen:

Applications in the field of process, engineering such as sugar juice filtration, waste water treatment, crude oil and natural gas production and vessel internals solving problems of solid / liquid and solid / gas separation, filtration of oils, greases, paints, food products, water, fuels, liquid cooling agents, chemicals etc.

Features for slotted filter v shaped wedge wire screen flat screen:

screen area consists of wedge shaped wires welded to crosswise profiled wires; the accuracy of the aperture width, totally smooth upper active screen area, high stability, high stress ability and long lifetime of the screen area; it is possible to select the profile of the wedge wire according to the characteristics and abrasion characteristics of the sorted material

Assembly instructions for slotted filter v shaped wedge wire screen flat screen:

the screen is fixed in technological machines (sorters, dehydration gutters and slides, filtration bottoms, malt kilns, fermentation reactors etc.) by various methods; it is usually screwed or wedged to the machine frame; final assembly forming of welded wedge wire screen is usually impossible, the required shape must be defined, from the construction point of view, before production

Advantages for slotted filter v shaped wedge wire screen flat screen:

-- A continuous slot opening which significantly increases the available open area, thus providing a greater access to the water bearing zone.

-- A 'V' shaped profile wire which avoids clogging and ensures uninterrupted flow.

-- A uniform and efficient well development due to the continuous slot opening.

Specifications of slotted filter v shaped wedge wire screen flat screen:

|

Profile Wire

|

|

|

|

|

|

|

|

|

|

Width(mm)

|

1.5

|

1.5

|

2.3

|

2.3

|

1.8

|

3.0

|

3.7

|

3.3

|

|

Height(mm)

|

2.2

|

2.5

|

2.7

|

3.6

|

4.3

|

4.7

|

5.6

|

6.3

|

|

Support Rod

|

|

|

|

|

|

Round

|

|

Width(mm)

|

2.3

|

2.3

|

3.0

|

3.7

|

3.3

|

Ø2.5~Ø5mm

|

|

Height(mm)

|

2.7

|

3.6

|

4.7

|

5.6

|

6.3

|

|

Packaging and Transportation of slotted filter v shaped wedge wire screen flat screen: