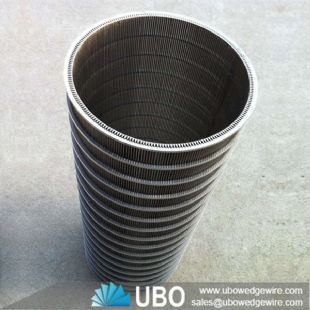

hot sale stainless steel wedge wire screen cylinders for Food Processing

| Category: | Wedge Wire Application |

|---|---|

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | Wedge wire screen cylinders |

| Application: | water-treating equipment, the environmental protection, the sea water transforms into the industrial water and life use water desalination treatment |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

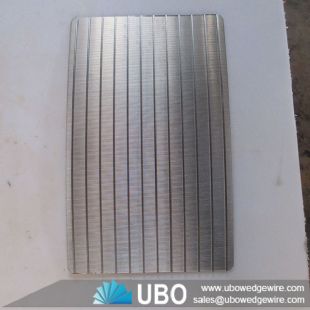

Details of hot sale stainless steel wedge wire screen cylinders for Food Processing

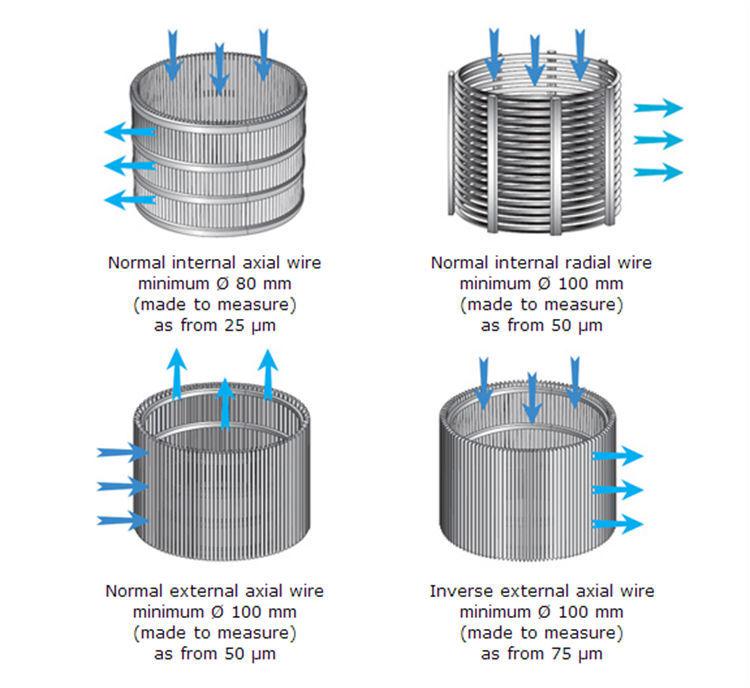

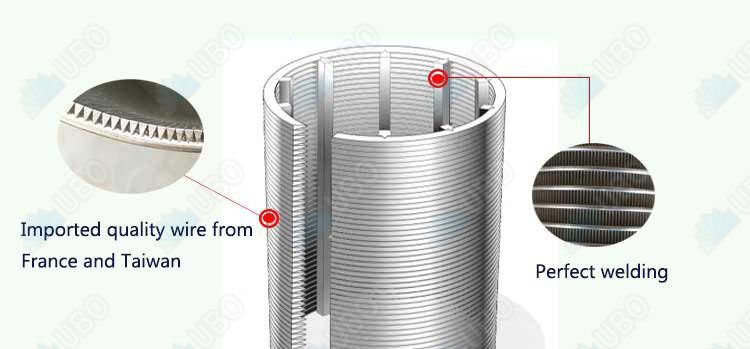

water screen filters pipe consists of wedge-shape profile wire and the longitudinal support rods. each intersecting point of these wires is fusion welded. so water well screen has sturdy constriction and good mechanical property.the wedge-shaped section plane can avoid blockage,and make sure of the unimpeded water. the consecutive slot have more open area,and water well screen can reduce the speed of the water entering to avoid the sand entering the screen under the great pressure,so wedge wire water well screen pipes can filter sand better. meanwhile the slot can change according to the real condition.

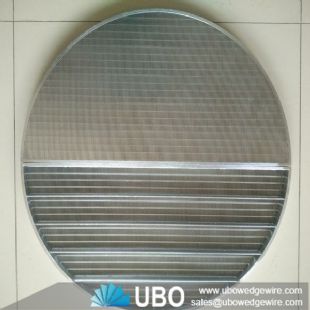

Usages of wedge wire screen cylinders for food processing:

Water well screen is a kind of filtered water tubing with the perforation. it can use with the deep well pump, dive the water pump, also in the water-treating equipment, the environmental protection, the sea water transforms into the industrial water and life use water desalination treatment, water softening treatment, the petroleum industry: The petroleum product terminal filters and so on the organic solution recycling filters.

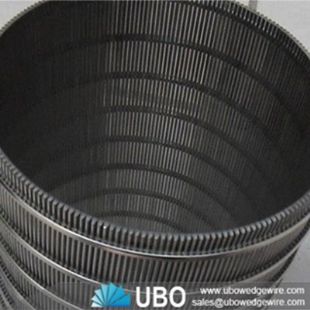

Features of wedge wire screen cylinders for food processing:

1) Each slot opening of sand control screen between adjacent wires is V-shaped, resulting from the special shape of the wire used to form the screen surface.

2) The V-shaped opens, designed to be non clogging, are narrowest at the outer face and widen inwardly.

3) Continuous-slot Wedge Wire deep well screens provide more intake area per unit area of screen surface than any other type.

4) For any given slot size, this type of screen has maximum open area.

Specifications of hot sale stainless steel wedge wire screen cylinders for Food Processing:

|

Screen Size

|

ID

|

OD

|

Female thread dismeter

|

||||

|

in

|

mm

|

in

|

mm

|

in

|

mm

|

in

|

mm

|

|

2

|

51

|

2

|

51

|

25/8

|

67

|

23/4

|

70

|

|

3

|

76

|

3

|

76

|

35/8

|

92

|

33/4

|

95

|

|

4

|

102

|

4

|

102

|

45/8

|

117

|

43/4

|

121

|

|

5

|

127

|

5

|

127

|

55/8

|

143

|

53/4

|

146

|

|

6

|

152

|

6

|

152

|

65/8

|

168

|

7

|

178

|

|

8

|

203

|

8

|

203

|

85/8

|

219

|

91/4

|

235

|

|

10

|

254

|

10

|

254

|

103/4

|

273

|

113/8

|

289

|

|

12

|

305

|

12

|

305

|

123/4

|

324

|

133/8

|

340

|

|

14

|

356

|

13 1/8

|

333

|

14

|

356

|

-

|

-

|

|

16

|

406

|

15

|

381

|

16

|

406

|

-

|

-

|

|

20

|

508

|

18 3/5

|

476

|

20

|

508

|

-

|

-

|

Packaging and Transportation of hot sale stainless steel wedge wire screen cylinders for Food Processing: