SS316 Johnson V Wire Screen for Wastewater Treatment

| Category: | Wedge Wire Application |

|---|---|

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | Wedge Wire Cylinder |

| Application: | waste water filtration, pulp and paper as well as mineral processing applications. Wedge wire or profile screen half cylinders can be added to an aug |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of SS316 Johnson V Wire Screen for Wastewater Treatment

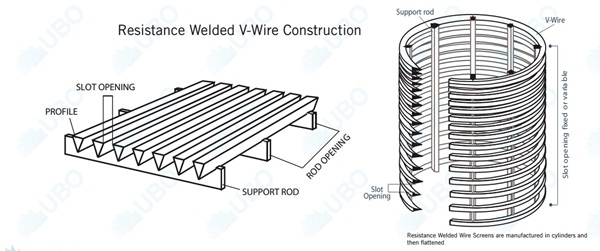

The V-shape section plane can avoid blockage, and make sure of the unimpeded water. The consecutive slot have more open area, and it can reduce the speed of the water entering to avoid the sand entering the screen under the great pressure, so water well screen can filter sand better.

Application for SS316 Johnson V Wire Screen for Wastewater Treatment:

Johnson screen products can use with the deep well pump, dive the water pump, also may use in the water-treating equipment, the environmental protection, the sea water transforms into the industrial water and life use water desalination treatment, running water treatment, water softening treatment, the petroleum industry: The petroleum product terminal filters and the chemical acid, the alkali liquid filters, the ethyl alcohol and so on the organic solution recycling filters.

Features for SS316 Johnson V Wire Screen for Wastewater Treatment:

Johnson v-wire screen consists of V-wire and the longitudinal support rods. Each intersecting point of these wires is fusion welded, so it has study constriction and good mechanical property.

Advantage for SS316 Johnson V Wire Screen for Wastewater Treatment:

1) Production process continuity: V-shaped profile wires creating slots which enlarge inwardly and therefore avoid clogging and minimize downtime.

2) Low maintenance costs: Separation at the screen surface which can easily cleaned by scraping or back washing.

3) Maximum process output: Precise and continuous slot openings resulting in accurate separation without loss off media.

4) Low operational costs: Large open area with an effective flow, high yield and a low pressure drop.

5) Long life: Welded at each intersection creating a strong and durable screen.

6) Reduced installation costs: supporting constructions eliminating costly support media and enabling a maximum flexibility in the design of components

7) Chemical and thermal resistant: A variety of corrosion resistant stainless steel materials and many exotic alloys suitable for high temperatures and pressures.

Specifications of SS316 Johnson V Wire Screen for Wastewater Treatment:

|

Specification (wedge wire): |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

|

Specification (support rod): |

Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

|

Note: other specifications available as per request |

|

|

Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material: |

galvanized low carton (LCG), stainless steel (304,316 etc.) |

|

Length |

up to 6 meters. |

|

Diameter |

from 25mm to 1200mm. |

|

End connection |

Plain beveled ends, flanged or threaded couplings |

Packaging and Transportation of SS316 Johnson V Wire Screen for Wastewater Treatment: