Rotary Drum Thickener manufacturer

| Category: | Wedge Wire Application |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | wedge wire screen |

| Application: | water treatment, oilfield, mining, food industry, chemical industry, papermaking industry, decoration. |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

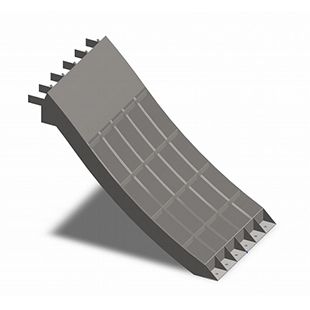

Details of Rotary Drum Thickener manufacturer

Drum screen used to separate materials by size, for example, separating the biodegradable fraction of mixed municipal waste or separating different sizes of mulch or crushed stone. Production rates can vary from 20 to 30 yards an hour to several hundred yards of material an hour based on number of factors described in this article.

Application for Rotary Drum Thickener manufacturer:

Trommel drum screen can be used in food processing, waste water filtration, pulp and paper as well as mineral processing applications. Wedge wire or profile screen half cylinders can be added to an auger or screw press to separate solids from liquids in food, waste water, minerals and industrial grit/chips from coolant.

Features and Benefits for Rotary Drum Thickener manufacturer:

1. High quality, robust structure by stainless steel for heavy duty task

2. Variable rotation speed to control the concentration of the thickened sludge

3. Double drums are available for large volume and continuous operation

4. Low power consumption; Low polymer consumption

5. Supplied complete with control panel and washing pump (Option)

Advantages for Rotary Drum Thickener manufacturer:

1. Press cake with the lowest moisture content;

2. Stainless steel SUS 304 construction, TIG reinforcing welding structure design;

3. Advanced slurry distribution unit;

4. Reliable and stable in operation;

5. Longer service time;

6. Low energy consumption;

7. Anti-abrasion and anti-corrosion protection;

8. Wide range application;

9. Easy to operate and maintenance

10. Compact structure, small space to install;

11. Automatic operation, reducing labour cost and intensity.

Specifications of Rotary Drum Thickener manufacturer:

|

Specification (wedge wire):

|

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70

Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00

|

|

Specification (support rod):

|

Width(mm): 2.30 3.00 3.30 3.70

Height(mm): 2.70 3.60 4.70 5.60 6.30

Round: From 2.50mm to 6.0mm

|

|

Note: other specifications available as per request

|

|

|

Slot size

|

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request.

|

|

Material:

|

galvanized low carton (LCG), stainless steel (304,316 etc.)

|

|

Length

|

up to 6 meters.

|

|

Diameter

|

from 25mm to 1200mm.

|

|

End connection

|

Plain beveled ends, flanged or threaded couplings

|

Packaging and Transportation of Rotary Drum Thickener manufacturer: