Pressure Screen for Pulp and Paper Machine

| Category: | Wedge Wire Application |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | wedge wire screen |

| Application: | deep well pump, dive the water pump, also may use in the water-treating equipment, the environmental protection, the sea water transforms into the ind |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of Pressure Screen for Pulp and Paper Machine

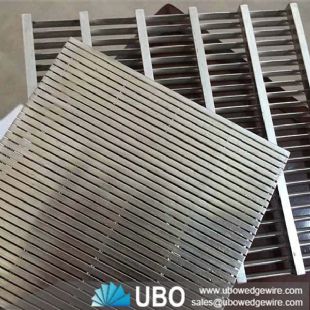

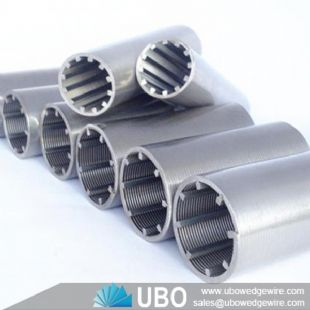

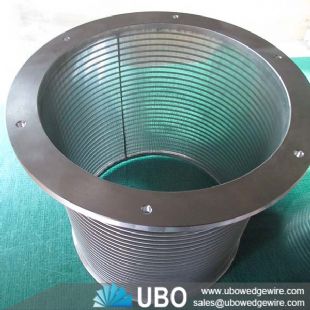

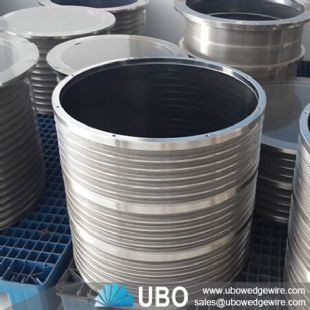

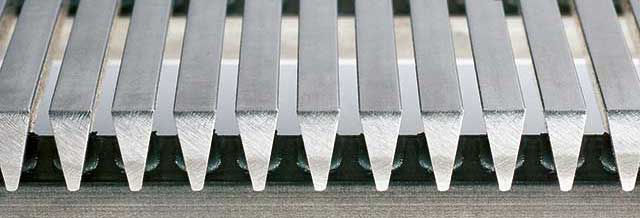

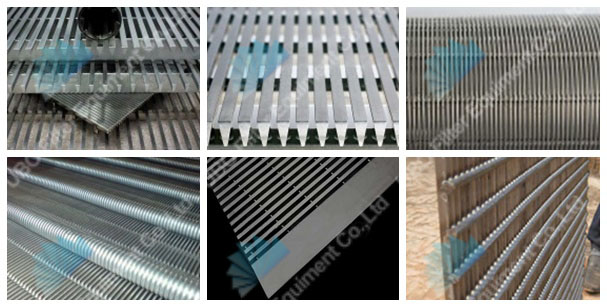

paper pulp wedge wire pressure screen is made by wrapping and welding stainless steel V-shaped profile wire around support rods under automatic wire screen machine. Each profile wire and support rod is welded by resistance welding,easily fit for pulp and paper industries for water clarification, cleaning, dewatering, pulp screening and fractionation, and other liquid/solid separation etc.

Application of Pressure Screen for Pulp and Paper Machine:

Pulp and paper plants use our screens in the wood yard, paper machines, recycling, dewatering, debris removal, fiber fractionalization, drying, water purification and other processes. Wedge Wire Screens are also applied in mineral processors, refinery, wastewater treatment and water supply systems.

Advantage of Pressure Screen for Pulp and Paper Machine:

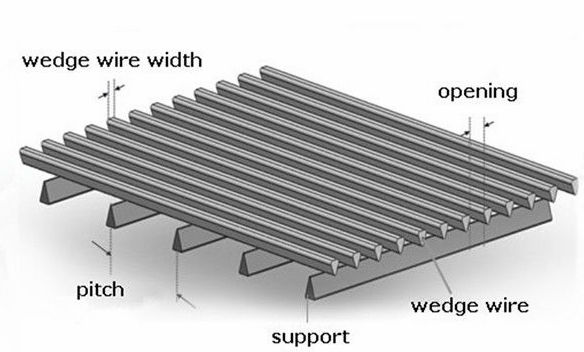

1) A continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone.

2) A uniform and efficient well development due to the continuous slot opening.

3) Ladder-like wire welded screens have a strong structure and high open area, as well as accurate slot dimension.

4) Ladder-like wire welded screens have the features of easy backwashing, last long, safety and reliability as well as low comprehensive cost.

Construction of Pressure Screen for Pulp and Paper Machine:

1) We use wedge-shaped profile wire in order to make the slot v-shaped. It can stop the impurities very well.

2) The wedge wire was welded on the support wire well-proportioned and have perfect roundness. Ensure the strainer have bigger filter area and non obstructive, avoid the high concentration of impurities.

3) After work for a period of time, the strainer can be back flush. It can use for many times.

Specifications of Pressure Screen for Pulp and Paper Machine:

|

Surface Profile |

W

|

H

|

Material |

|

10S |

0.75

|

1.425

|

S304,S316L Hastelloy, Monel alloy of nickel and titanium, and other stainless steel |

|

11SL |

10.75

|

1.8

|

|

|

22S |

1.8

|

3.7

|

|

|

4S |

0.45

|

1.2

|

|

|

50SL |

3.4

|

7.5

|

|

Surface Profile

|

W

|

H

|

Material

|

|

Q22

|

2

|

2.28

|

S304,S316L Hastelloy, Monel alloy of nickel and titanium, and other stainless steel |

|

Q35

|

3

|

5

|

|

|

Q53

|

4

|

3

|

|

|

D56

|

4

|

5.6

|

|

|

D45

|

3.8

|

6.0

|