Continuous-slot stainless steel 201 water well screen casing pipes supplier

| Category: | Wedge Wire Application |

|---|---|

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | Wedge Wire Cylinder |

| Application: | waste water filtration, pulp and paper as well as mineral processing applications. Wedge wire or profile screen half cylinders can be added to an aug |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of Continuous-slot stainless steel 201 water well screen casing pipes supplier

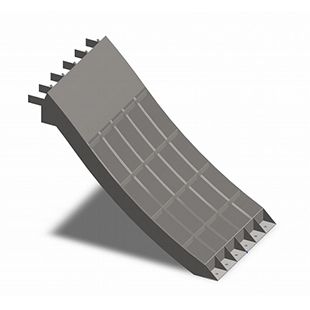

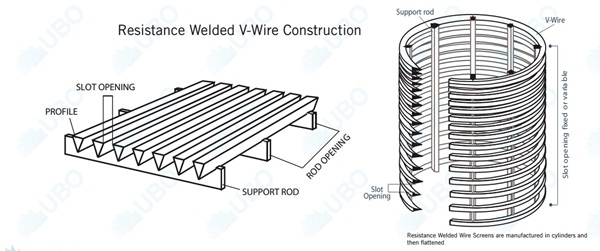

The Weld wedge wire screen filter tube is made up of rods and warp. The rod can be round wire, triangular wire or trapezoid wire. The warp is triangular wire (V-shaped wire). Water well screens have a structure and high open area, as well as accurate slot dimension. At the same time,water well screen have heat-resisting, anti-corrosive, good machine capability, last long, safety and reliability and so on characteristics. It can be used in many kinds of medium filtering.

Application for Continuous-slot stainless steel 201 water well screen casing pipes supplier:

The continuous-slot screens, widely used throughout the world for water, oil, and gas wells, is the dominant screen type used in the water well industry.

Advantage for Continuous-slot stainless steel 201 water well screen casing pipes supplier:

1. A continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone

2. A V-shaped profile wire which avoids clogging and ensures an uninterrupted flow.

3. A uniform and efficient well development due to the continuous slot opening.

4. Ladder-like wire welded screens have a strong structure and high open area, as well as accurate slot dimension.

5. Ladder-like wire welded screens have the features of easy backwashing, last long, safety and reliability as well as low comprehensive cost.

Production Methods for Continuous-slot stainless steel 201 water well screen casing pipes supplier:

1. Winding cold-rolled wire, approximately triangular in cross section, around a circular array of the longitudinal rods.

2. The wire is attached to the rods by welding, producing rigid one-piece units having high strength characteristics at minimum weights.

3. Slot opening are manufactured by spacing successive turns of the outer wire to produce the desired slot size. All slots should be clean and free of burns and cuttings.

4. Process: for carbon steel continuous slot screens, we can paint black lacquer or silver lacquer, or galvanized, stainless steel continuous slot screens will be polished.

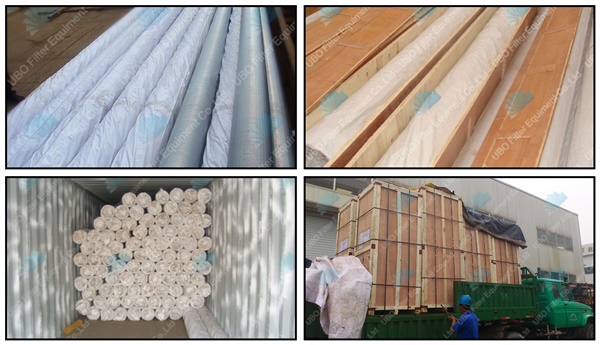

5. Package: inner bubble bag and outer woven bag. Wooden box can be employed if needed.

Specifications of Continuous-slot stainless steel 201 water well screen casing pipes supplier:

|

size |

inner diameter |

outer diameter |

|||

|

in

|

mm

|

in

|

mm

|

in

|

mm

|

|

2

|

51

|

2

|

51

|

25/8 |

67 |

|

3

|

76

|

3

|

76

|

35/8 |

92

|

|

4

|

102

|

4

|

102

|

45/8 |

117

|

|

5

|

127

|

5

|

127

|

55/8 |

143

|

|

6

|

152

|

6

|

152

|

65/8 |

168

|

|

8

|

203

|

8

|

203

|

85/8 |

219

|

|

10

|

254

|

10

|

254

|

103/4 |

273

|

|

12

|

305

|

10

|

305

|

123/4 |

324

|

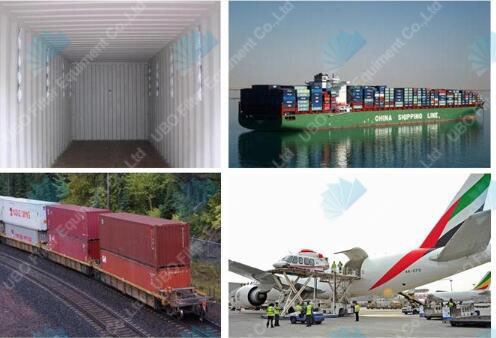

Packaging and Transportation of Continuous-slot stainless steel 201 water well screen casing pipes supplier: