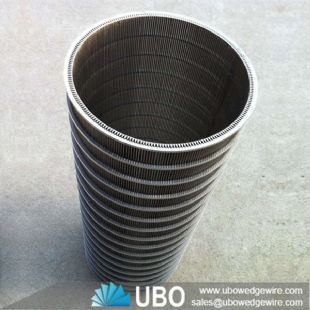

stainless 304 wedge wire screen Wedge Wire screen water well screen cylinder

| Category: | Wedge Wire Pipe&Cylinder |

|---|---|

| Material: | stainless steel |

| Properties: | Wedge wire screen cylinders |

| Application: | oil , gas , chemical , food or beverage , mining , waste water management |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of stainless 304 wedge wire screen Wedge Wire screen water well screen cylinder

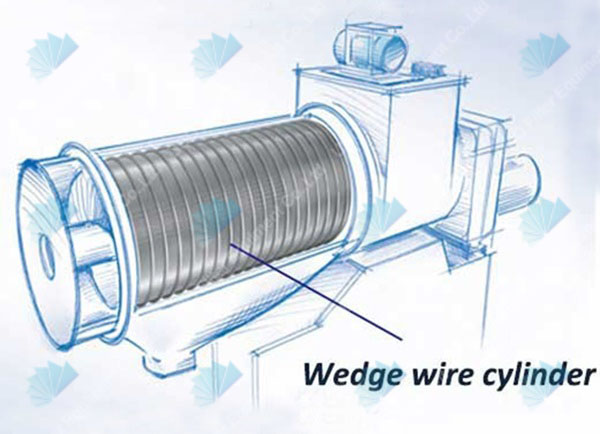

Wedge Wire cylinders also known as wedge wire rotary drum screens are manufactured with high-quality stainless steel. YUBO custom designs stainless 304 wedge wire screen water screen cylinders for wide ranges of industrial filtration.

Our offered products are extensively demanded by various industries and are manufactured in accordance with the industry set norms and guidelines. Post-production, we test each product on various stages to give our clients

Application for stainless 304 Wedge Wire screen water screen cylinder:

Wedge wire screen have a lot of applications like using in oil , gas , chemical , food or beverage , mining , waste water management or coal separation .

Features for stainless 304 Wedge Wire screen water screen cylinder:

A continuous slot opening which significantly increases the available open area, thus providing a greater access to the water bearing zone.

High filtration efficiency

Large opening area

Strong pressure capacity

Long lasting

Technology for stainless 304 Wedge Wire screen water screen cylinder:

The technology used for manufacturing stainless 304 wedge wire screen water screen cylinders involves several steps.

1. Material selection: The first step is to select the appropriate material for the wedge wire screen cylinder. Stainless steel 304 is a popular choice due to its excellent corrosion resistance and durability.

2. Wire drawing: The selected stainless steel wire is drawn through a series of dies to achieve the desired diameter and shape.

3. Welding: The wires are then welded together to form a V-shaped profile. The welding process can be done using various techniques, including resistance welding, TIG welding, and plasma welding.

4. Shaping: The welded wire is then shaped into a cylinder using specialized machinery. The cylinder can be made in various sizes and shapes, depending on the application.

5. Surface treatment: The surface of the cylinder is treated to improve its corrosion resistance and durability. This can be done through various methods, including electro-polishing, passivation, and coating.

6. Quality control: The finished wedge wire screen cylinder undergoes rigorous quality control checks to ensure that it meets the required specifications.

Specifications of stainless 304 wedge wire screen Wedge Wire screen water well screen cylinder:

|

size

inch

|

inner dia

inch

|

outer dia

inch

|

|

2

|

2

|

25/8

|

|

3

|

3

|

35/8

|

|

4

|

4

|

45/8

|

|

5

|

5

|

55/8

|

|

6

|

6

|

65/8

|

|

8

|

8

|

85/8

|

|

10

|

10

|

103/4

|

|

12

|

12

|

123/4

|

|

14

|

131/18

|

14

|

|

16

|

15

|

16

|

|

20

|

183/4

|

20

|

Packaging and Transportation of stainless 304 wedge wire screen Wedge Wire screen water well screen cylinder: