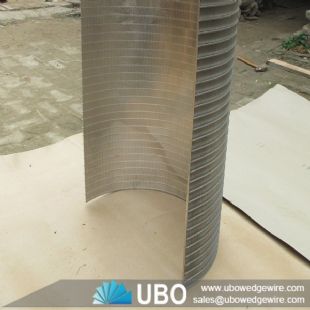

wedge wire screen panel/sieve bend screen

| Category: | Sieve Bend Screen |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | wedge wire screen |

| Application: | water-treatment , water well drilling ,oil well drilling ,mineral processing, coal-cleaning plant |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of wedge wire screen panel/sieve bend screen

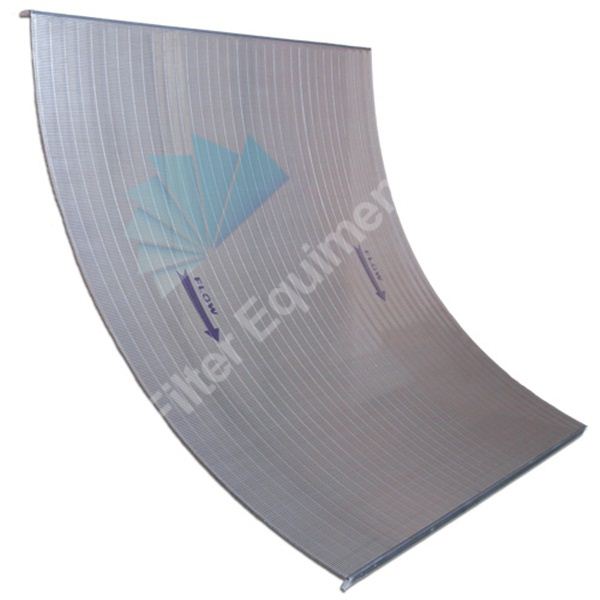

Wedge wire screen panel/sieve bend screen of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. Wedge wire screen panel/sieve bend screen has greater capacity than a flat screen due to forces exerted as material flows against the curved surface.

Application of wedge wire screen panel/sieve bend screen

Wedge wire screen panel/sieve bend screens are manufactured to suit a wide range of industries such as Sugar, Coal Mining & Quarrying, Mineral Processing, Cement, and Industrial & Urban Effluent Treatment etc. Sieve bend screens are also used as a pre-filter in urban & industrial waste treatment plants to improve the performance of the clarifier by drastically reducing the load. Widely used for fiber removal in Starch industry.

Features of wedge wire screen panel/sieve bend screen

Energy Efficient - operates with no moving parts and with no energy input.

Space Efficient - treats up to 122 litres per second per square metre of floor space.

Quiet Operation - no moving parts means no mechanical or electrical vibrations.

Accurate Sizing - can be used for sizing solid particles down to 0.2 mm (0.008").

Low Maintenance - the profile wire screen resists clogging by near-size particles, and the all-stainless steel construction ensures a long, corrosion-free installation.

Easy Screen Replacement - a typical screen can be replaced in 10 minutes with no tools.

Flexible Design - we can supply units with any features you may require.

Work Principle of wedge wire screen panel/sieve bend screen

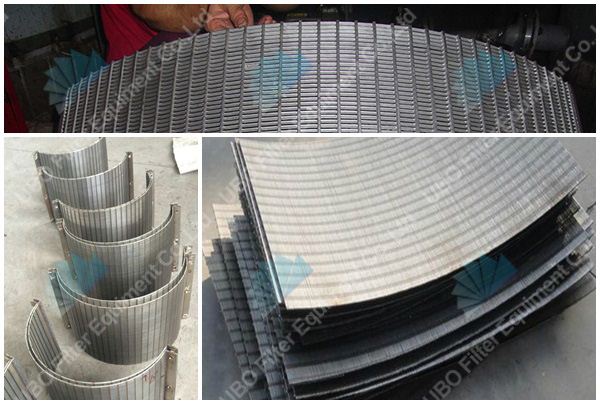

Wedge wire screen panel/sieve bend screen mainly works as fitting panels for rotary screens or vibrating screens. Each unit is designed to suit the specific requirements of the customer. Consisting of a basic outer casing, which can be manufactured in mild steel or stainless steel, each unit incorporates a distribution chamber and feed weir; over which the effluent passes onto the wedge wire panel which is set at right angles to the flow to enable the separating process to commence.

The separated solids collect on the lower half of the screen to drain and compact, they then slide by gravity onto a solids discharge chute.

Specifications of wedge wire screen panel/sieve bend screen:

|

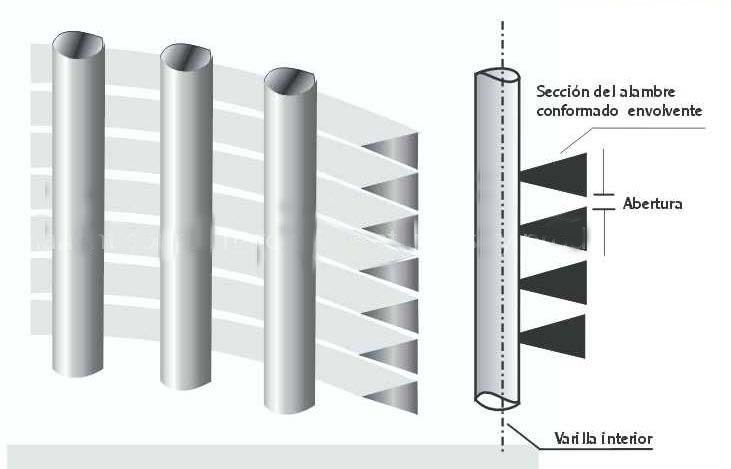

Specification (wedge wire):

|

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70

Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00

|

|

Specification (support rod):

|

Width(mm): 2.30 3.00 3.30 3.70

Height(mm): 2.70 3.60 4.70 5.60 6.30

Round: From 2.50mm to 6.0mm

|

|

Note: other specifications available as per request

|

|

|

Slot size

|

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request.

|

|

Material:

|

galvanized low carton (LCG), stainless steel (304,316 etc.)

|

|

Length

|

up to 6 meters.

|

|

Width

|

from 25mm to 1200mm.

|

|

End connection

|

Plain beveled ends, flanged or threaded couplings

|

Packaging and Transportation of wedge wire screen panel/sieve bend screen: