stainless steel Wedge Wire sieve bend screen for coal dewatering

| Category: | Sieve Bend Screen |

|---|---|

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | wedge wire screen |

| Application: | Sugar, Coal Mining & Quarrying, Mineral Processing, Cement |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of stainless steel Wedge Wire sieve bend screen for coal dewatering

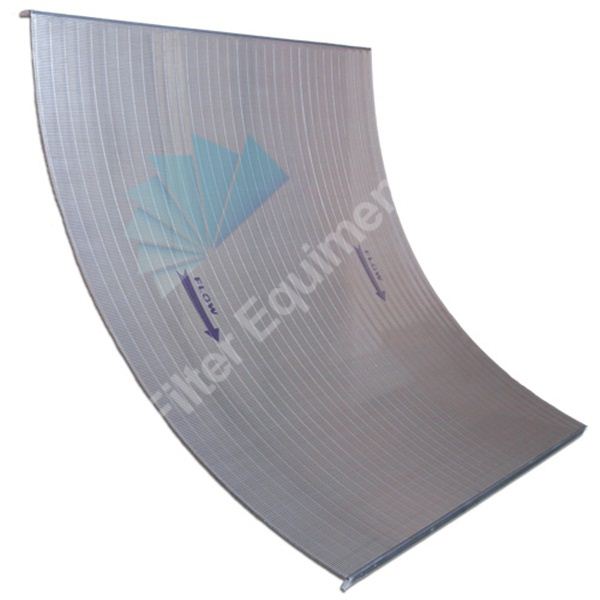

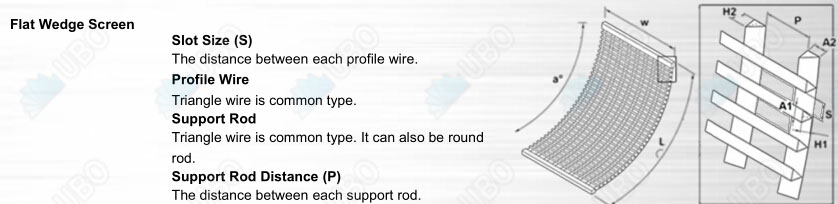

Sieve Bend Screens also known as side hill screens, parabolic screens, run down screens, gravity screens and DSM screens, can be custom designed to separate solids. Sieve Bends are cross-flow screens. The profile wires are slightly tilted so that the leading edge is position higher which greatly increases the dewatering capacity.

Applications for stainless steel Wedge Wire sieve bend screen for coal dewatering:

Sieve bends are manufactured to suit a wide range of industries such as Sugar, Coal Mining & Quarrying, Mineral Processing, Cement, and Industrial & Urban Effluent Treatment etc. Sieve bend screens are also used as a pre-filter in urban & industrial waste treatment plants to improve the performance of the clarifier by drastically reducing the load. Widely used for fiber removal in Starch industry.

Advantages for stainless steel Wedge Wire sieve bend screen for coal dewatering:

• continuous slot screens, stronger and more durable

• more open area, very precise openings

• virtually non-clogging and reduce media abrasion

• easier installation and long-term operating and cost benefits

Features for stainless steel Wedge Wire sieve bend screen for coal dewatering:

Low Headroom - only 1.1 metres (44") tall for the 900 mm arc length unit.

Energy Efficient - operates with no moving parts and with no energy input.

Space Efficient - treats up to 122 litres per second per square metre of floor space.

Quiet Operation - no moving parts means no mechanical or electrical vibrations.

Accurate Sizing - can be used for sizing solid particles down to 0.2 mm (0.008").

Low Maintenance - the profile wire screen resists clogging by near-size particles, and the all-stainless steel construction ensures a long, corrosion-free installation.

Easy Screen Replacement - a typical screen can be replaced in 10 minutes with no tools.

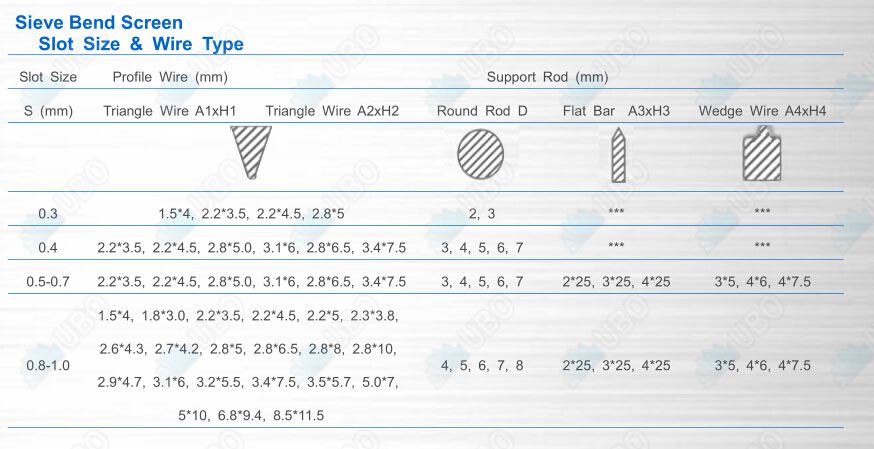

Specifications of stainless steel Wedge Wire sieve bend screen for coal dewatering:

Packaging and Transportation of stainless steel Wedge Wire sieve bend screen for coal dewatering: