stainless steel Slot and V-Wire Wrap Water Well Screen

| Category: | Sieve Bend Screen |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | stainless steel |

| Application: | Sugar, Coal Mining & Quarrying, Mineral Processing, Cement, and Industrial & Urban Effluent Treatment etc |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of stainless steel Slot and V-Wire Wrap Water Well Screen

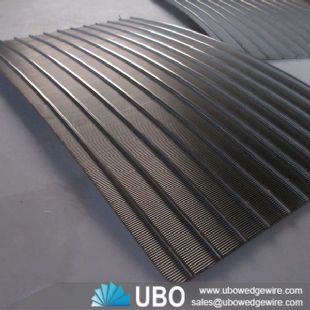

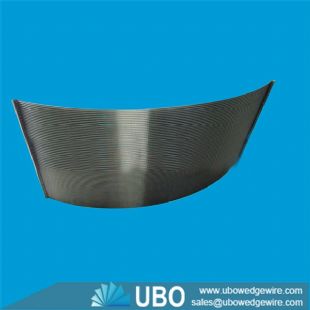

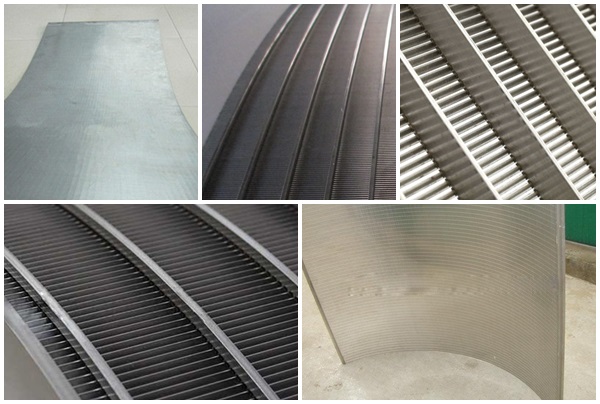

Sieve Bend Screens also known as side hill screens, parabolic screens, run down screens, gravity screens and DSM screens.

A sieve bend consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat wedge screen due to forces exerted as material flows against the curved surface.

Sieve Bends are cross-flow screens. The profile wires are slightly tilted so that the leading edge is position higher which greatly increases the dewatering capacity.

Application for stainless steel Slot and V-Wire Wrap Water Well Screen:

They are used in industries such as Sugar, Coal Mining & Quarrying, Mineral Processing, Cement, and Industrial & Urban Effluent Treatment etc. Sieve bend screens are also used as a pre-filter in urban & industrial waste treatment plants to improve the performance of the clarifier by drastically reducing the load. Widely used for fiber removal in Starch industry.

Features for stainless steel Slot and V-Wire Wrap Water Well Screen:

Efficient separation with sharp cut;

Unique profile wire welded wege wire sieve bend;

Safe and stand equipment;

Simple screen replacement design;

Pneumatically operated washing jet for screen surface.

Advantage for stainless steel Slot and V-Wire Wrap Water Well Screen:

1 Excellent roundness

2 Very good slot width precision

3 High mechanical load capacity

4 No form closure connection that would allow vibration of the profiled bars

5 Automated welding process for high-precision manufacturing

6 Perfectly adjusted screen basket profiles

7 Available for all screens

8 Surface finishing as required

Specifications of stainless steel Slot and V-Wire Wrap Water Well Screen:

|

Size

(inch)

|

O.D

(mm)

|

Slot

(inch)

|

Collapse Strength

(Psi)

|

Tensile Weight

(Ton)

|

Wrap(thick*deep)

(mm)

|

Rods

(mm)

|

|

4

|

117

|

0.04

|

395

|

6

|

2.2*3.0

|

3.8mm/22

|

|

4

|

114.3

|

0.04

|

395

|

6

|

2.3*3.0

|

3.8mm/22

|

|

6

|

168.3

|

0.04

|

252

|

8

|

2.3*3.5

|

3.8mm/32

|

|

8

|

219.1

|

0.01

|

399

|

10.5

|

3.0*5.0

|

3.8mm/48

|

|

8

|

219.1

|

0.02

|

370

|

10.5

|

3.0*5.0

|

3.8mm/48

|

|

8

|

219.1

|

0.04

|

323

|

10.5

|

3.0*5.0

|

3.8mm/48

|

|

10

|

273.1

|

0.01

|

206

|

11

|

3.0*5.0

|

3.8mm/50

|

|

10

|

273.1

|

0.02

|

191

|

11

|

3.0*5.0

|

3.8mm/50

|

|

10

|

273.1

|

0.04

|

167

|

11

|

3.0*5.0

|

3.8mm/50

|

Packaging and Transportation of stainless steel Slot and V-Wire Wrap Water Well Screen:

1.Each product is packed with bubble bag and then few bags to a wooden case (fumigation certificate)

2.We have a very trust forwarding company cooperate for long time and establish a solid partnership,of course,you can also arrange forward to take products from our factory.