Wedge Wire DSM Screens for Water Treatment

| Category: | Sieve Bend Screen |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | wedge wire screen |

| Application: | water-treatment , water well drilling ,oil well drilling ,mineral processing, coal-cleaning plant |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of Wedge Wire DSM Screens for Water Treatment

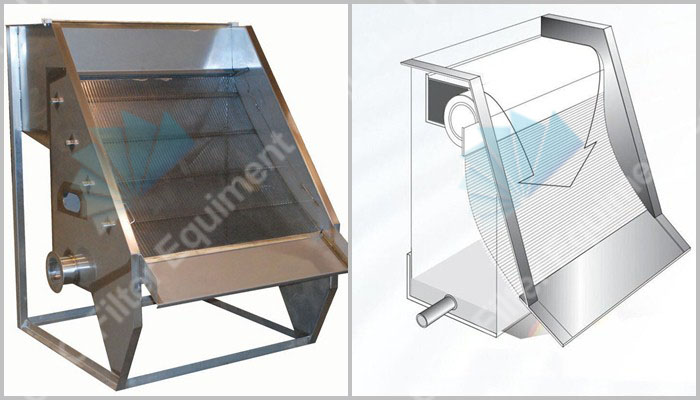

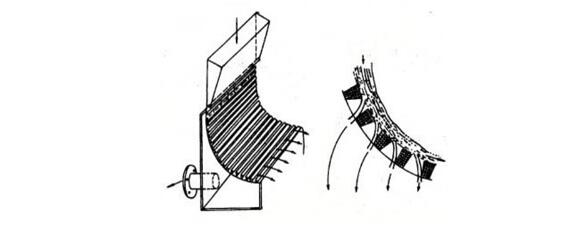

Wedge wire dsm screens also known as side hill screens, parabolic screens, run down screens, gravity screens and DSM screens, can be custom designed to separate solids from liquids in various applications including food processing, pulp and paper, waste water cleanup, surface water intakes, corn wet milling, coal preparation, and gold recovery.

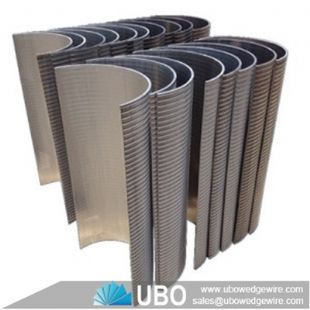

Wedge wire dsm screens consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat wedge screen due to forces exerted as material flows against the curved surface.

Applications of Wedge Wire DSM Screens for Water Treatment

Wedge wire dsm screens in a wide range of architectural situations such as floor grates to cover water run off drains in places such as driveways, car parks, shopping centres or malls. They can be constructed to carry pedestrian traffic or much heavier traffic such as fork lifts or standard vehicular traffic.

Features of Wedge Wire DSM Screens for Water Treatment

-- Reduced equipment and installation costs

-- Low mantenance costs(No moving parts)

-- Better flow rate and finer fiber removal

-- Little space needed

-- Wide range of applications

-- Longer liftetime

Advantages of Wedge Wire DSM Screens for Water Treatment

A continuous slot opening which significantly increases the available open area, thus providing a greater access to the water bearing zone.

A 'V' shaped wedge wire which avoids clogging and ensures uninterrupted flow.

A uniform and efficient well development due to the continuous slot opening.

Offering great strength. precision, long service life.

Specifications of Wedge Wire DSM Screens for Water Treatment:

|

Specification (wedge wire): |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

|

Specification (support rod): |

Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

|

Note: other specifications available as per request |

|

|

Slot Size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material: |

galvanized low carton (LCG), stainless steel (304,316 etc.) |

|

Length |

up to 6 meters. |

|

Width |

from 25mm to 1200mm. |

|

Radian |

60º 120º or according to your special requirement |

Packaging and Transportation of Wedge Wire DSM Screens for Water Treatment: