Stainless steel filter and filler nozzle for diesal tank

| Category: | Filter Nozzle |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | wedge wire screen |

| Application: | water-treatment , water well drilling ,oil well drilling ,mineral processing, coal-cleaning plant |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

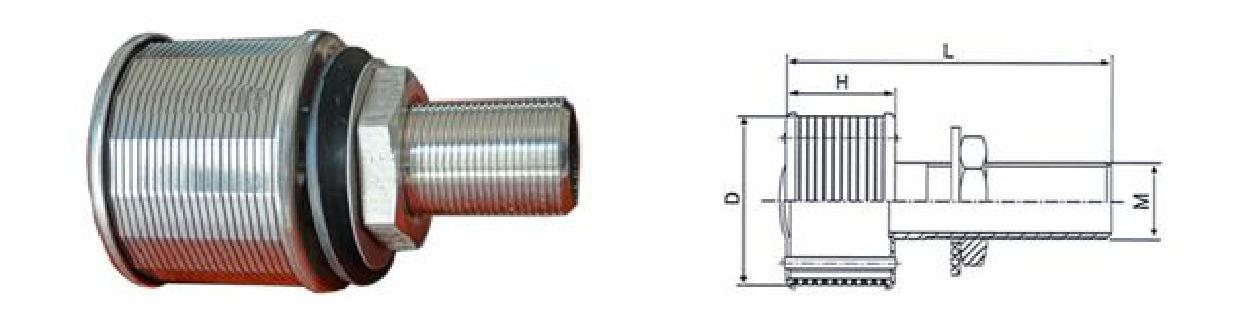

Details of Stainless steel filter and filler nozzle for diesal tank

Stainless steel filter and filler nozzles are made from V shaped profile wire, which is spirally wound around a cage of longitudinal support rods. Each intersecting point of these wires is fusion welded, with an unique welding process. This spacing gives passage for water to enter. The entire process is completed on fully computerized machines. The pitch of winding gives different spacing between two adjacent turns of wire.

Feature of Stainless steel filter and filler nozzle for diesal tank

Stainless steel filter and filler nozzle have the features of great strength, precision, long service life and a wide range of applications in the field of process and engineering such as waste water treatment, sugar juice filtration, crude oil and natural gas production and vessel internals solving problems of solid / liquid and solid / gas separation, filtration of oils, greases, water, fuels, paints, food products, liquid cooling agents, and chemicals etc.

Advantages of Stainless steel filter and filler nozzle for diesal tank

1·Type 316L stainless steel construction.

2·Continuous slot design provides increased open area for better collection.

3·Standard nozzles are 2in./51mm diameter and can be attached to the plate either with threaded end fittings or with“L”bolts.

4·Standard slot opening is typically range between 0.006”(0.15mm), and 0.020in./0.50mm wide suitable for 40 to 50 mesh size media, Other slot sizes are also available.

5·Wedge wire screen is highly resistant to plugging.

6·Choice of either 3/4”NPT or 1”NPT fittings are available from stock. Other styles, such as tee-bolt mountings, and drop tubes are readily available.

7·Less expensive than other screen of equal efficiency.

Usage of Stainless steel filter and filler nozzle for diesal tank

used widely in down-flow reactors for liquid/solid or gas/solid separation. The liquid or gas can flow through the nozzles while the solids are retained in the vessel by the nozzles.

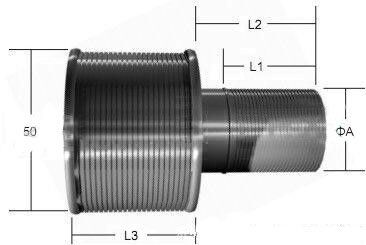

Specifications of Stainless steel filter and filler nozzle for diesal tank:

|

Type |

Slot |

Dimension |

Flow area |

|||

|

D |

H |

L |

M |

|||

|

A |

0.25 |

Φ45 |

40 |

90 |

M20 |

450m3 |

|

A1 |

0.25 |

Φ45 |

40 |

90 |

M24 |

500m3 |

|

(flow 0.5T/H) |

||||||

|

B |

0.25 |

Φ53 |

45 |

100 |

M24 |

570m3 |

|

(flow 1T/H) |

||||||

|

B1 |

0.25 |

Φ53 |

45 |

100 |

M32 |

600m3 |

|

(flow 1.5T/H) |

||||||

|

B3 |

0.25 |

Φ57 |

55 |

110 |

M32 |

800m3 |

|

(flow 2T/H) |

||||||

|

C |

0.2-0.5 |

Φ70 |

45 |

110 |

M32 |

800m3 |

|

C1 |

0.2-0.5 |

Φ70 |

55 |

120 |

M32 |

1000m3 |

Packaging and Transportation of Stainless steel filter and filler nozzle for diesal tank: