What are the causes of sieve plate damage too fast

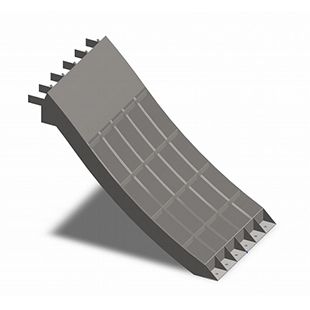

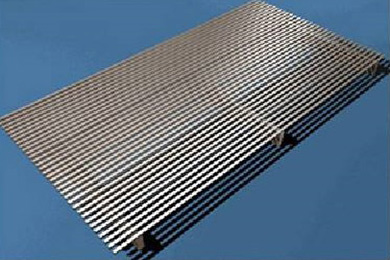

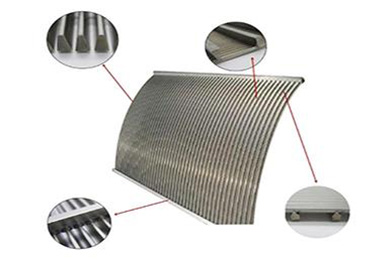

Sieve plate also known as porous plate, has good wear resistance, long service life, moisture resistance and wear resistance. It is suitable for ore washing, screening, grading, deslagging, desliming, dehydration and other mechanical industries.

The tension of sieve plate is not enough. The reason for the damage and the method of repair cause the sieve plate to vibrate, usually along the edge of the sieve plate or the edge banding.

The quality of sieve plate is unqualified. Generally, the sieve plate has the upper sieve layer and the lower stress layer. It is required that the two layers are closely connected. If the sieve plate process is poor, when the stress layer at the bottom of the sieve plate is tight, the sieve layer is not tightened, and the throwing force of drilling cuttings is greatly reduced during operation, so the drilling cuttings cannot be discharged.

In many cases, customers and friends encounter various problems and need long-term work of vibrating screen. It may be used for a long time, and the vibrating screen works continuously for a long time, so that the vibrating screen "never stops" is also a key point leading to rapid damage.

No maintenance. Although the damage sometimes has a lot to do with the quality problem, if the vibrosieve bought back by oneself does not take care of it, the damage speed will also be accelerated.

When debugging the steering error of the vibrating motor, according to the previous experience of using the single axis vibrating screen or the linear vibrating screen, the field operators think that as long as the drilling cuttings move forward, but this method is not suitable for the translation of the elliptical vibrating screen. If the motor rotates to the inner side by mistake, the ejection angle is also 45 ° forward, but the cuttings have the force to roll backward. At this time, the cuttings move forward much slower, stay on the screen for a long time, and even the cuttings cannot be discharged.

The above is about sieve plate. I hope it can help you.