Introduction of curved wedge wire screen

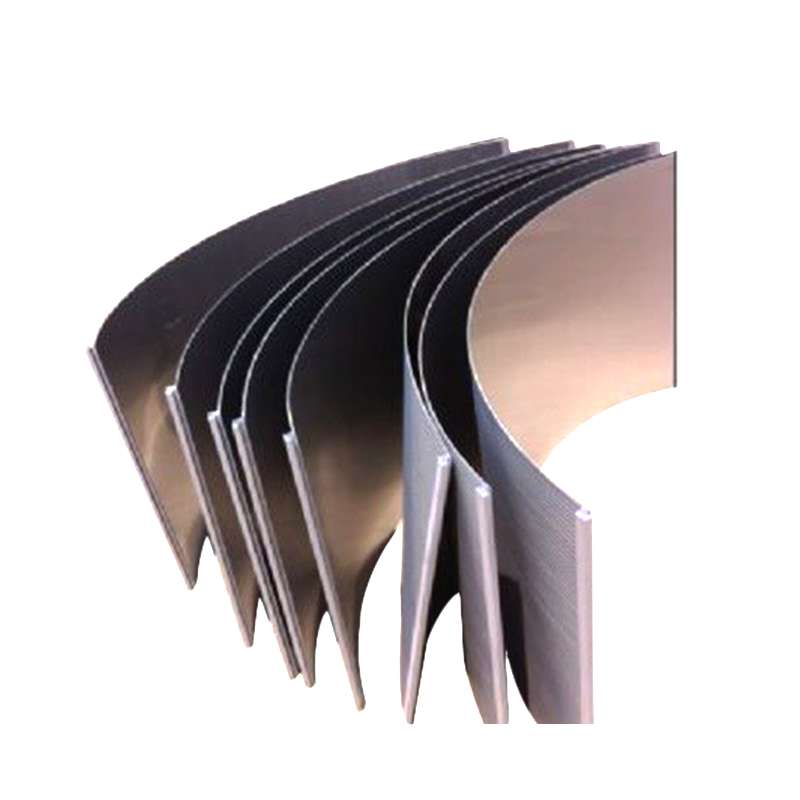

The curved wedge wire screen is mainly used for pre-dewatering, desliming, de-intermediation operations and grading slime recovery of materials in coal preparation plants and ore dressing plants. The curved wedge wire screen surface and the screen frame adopt the pivot-specific structure, which can rotate 180 degrees to achieve uniform wear, extend the service life, and operate flexible and convenient. It has also been applied in metallurgy, chemical and other industries.

The curved wedge wire screen can be made into different radii and different angles according to needs. There are five commonly used angles: 45°, 60°, 90°, 180° and 270°. Artesian arc screens often use arc angles of 45°, 60° and 90° and are used in coal preparation plants and ore dressing plants. Pressure arc screens, often with 180° and 270° arcs, are used for grading operations in the grinding process in the cement industry.

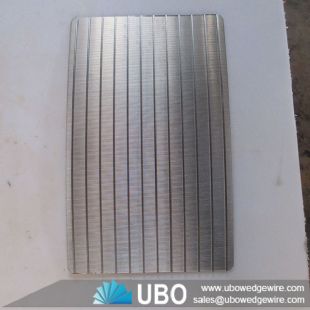

The arc-shaped screen is composed of an arc-shaped surface formed by wedge-shaped screen bars. There are horizontal gaps between the screen bars, usually with a width of 350 microns. The liquid flow to be screened enters through the headbox and flows to the sieve plate through a weir nozzle by gravity. When the suspension flows along the sieve plate, the thin layer of water is cut off by the sieve plate sticks and passes along with the fine particles Sieve slit.