How to solve the clogging of Sieve Bend Screen Strainer Filter

I.reasons for blocking of screen bending screen filter:

The screen surface of the curved screen filter moves in a straight line under the action of the vibration exciter.The particles eject and fall down under the vibration of the screen surface.The ejections and falls of the materials have impact on the screen surface,so that the particles smaller than the sieve hole are screened through,so that the materials can be classified according to the size of the particles.There are many factors that affect the permeability of the material,but there are two main categories.One is the various characteristics of the material itself,and the other is the structure of the bent screen filter.

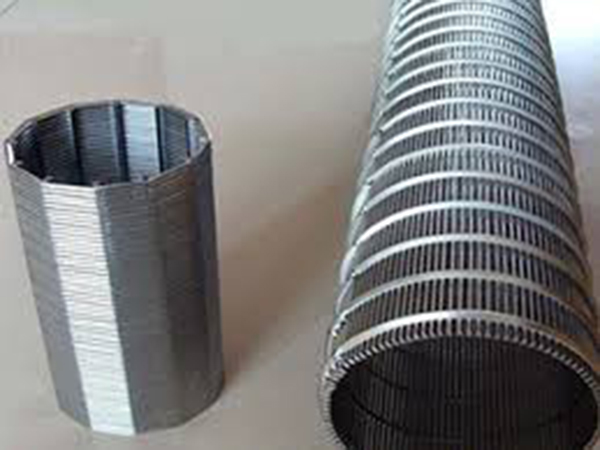

Through the analysis,it is found that the main reason for the screen blocking of the bent screen filter is that there are many fine materials in the screening materials,which are close to the size of the screen hole,and are easy to get stuck on the screen hole,causing blocking; in addition,the screening materials are also relatively wet,and the wet fine particles will stick to each other and adhere to the screen surface,making the screening process difficult to complete.It is difficult to change the properties of the materials,so the solution to the blocking problem should be mainly from the structural form of the curved screen filter and the screen structure.

2.There are two main ways to solve the problem:

The structure and vibration strength of the curved screen filter and the structure of the screen mesh.

From the perspective of the development of the structural form of the curved screen filter,there are many kinds of curved screen filters,such as probability screen,flip screen,equal thickness screen,etc.,which have some progress in solving the problem of blocking,but their screens can not be effectively self-cleaning,generally only used for the classification of materials above 13 mm.

As the materials are screened in layers on the screen surface,the larger the effective screening area is,the larger the screening capacity per unit time on the screen surface is,and the higher the production efficiency will be.Therefore,in the case of a certain amount of treatment,increasing the screen area can reduce the thickness of the material layer and improve the screening efficiency to a certain extent,but at the same time,it will make the screen bending filter too bulky and increase the cost of equipment and civil engineering.

If the vibration intensity is too small,the materials will not be loose enough to affect the screen penetration.Increasing the vibration intensity can improve the screening efficiency.However,if the fine-grained materials are wet,the materials will be tightly adhered to the screen.The overall movement of the material layer is difficult to stratify.The improvement of the vibration intensity does not obviously solve the blocking problem.Moreover,the vibration intensity is too large for the side plate,tube beam,vibration exciter,etc.of the linear vibration screen Damage and reduce the service life of vibrating screen.