Why using wedge wire rotary drum screen

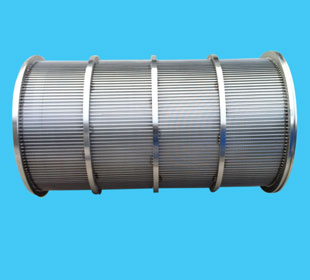

Rotary drum screen is a rotating wedge wire cylinder which is fed externally. As the solids are captured on the face of the screen, they are removed by a discharge blade. The mass influent constantly washing the screen, resulting in continuous self cleaning screen surface. The continuous and automatic self-cleaning effect makes it possible to use higher hydraulic and solids loading onto the screen in comparison with other types of screening equipment. Therefore, substantial capital and operational cost are saving.

Why using wedge wire rotary drum screen

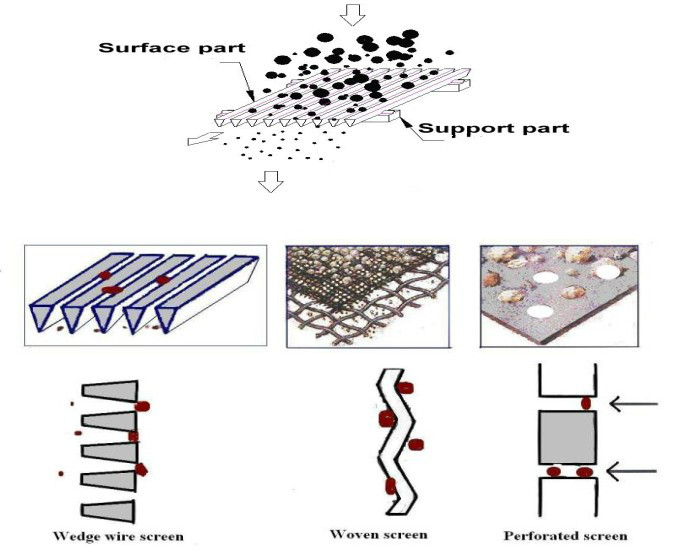

Wedge wire is a welded stainless steel structure, mainly used for filtration, separation and retention media. It consists of wedge wire surface which was usually v shaped and are resistance welded onto support part. The distance between the surface part is controlled very accurately, as it forms the slot through which the filtrate flows. In case of V-shaped surface part conical slots are created

.

The separation efficiency of Wedge wire screen is better than traditional Woven screen and perforated screen. The partials are easy to get through the uniform slots of wedge wire screen and not easy to get clogged due to high open rate.

Applications of Rotary Drum Screen

a) Vegetarian Industry

b) Drink Industry

c) Can Food Industry

d) Paper &Pulp

e) Power Plant

f) Liquor Plant

g) Hoggery & Slaughter House

h) FishPond & Hatchery

Benefits of Rotary Drum Screen

a) Low cost and reduce pollution loading

b) Saving room

c) Easy Installation and operation

d) Low operation cost

e) High efficiency

f) For high Temp and Viscosity Wastewater

Wedge wire has the following advantages:

1) Non-clogging: the continuous slot formed by the V-shaped surface wires ensures a two-point contact between the particles and the slot which minimizes clogging

2) High-precision slot sizes: precise slot sizes are available to meet customer´s requirements

3) Surface filtration: the V-shaped surface wires allow easy cleaning by mechanical scraping or back flushing

4) The feed is evenly distributed over the entire screen surface which results in even wear and increased screen life

5) Strong construction: for most applications, the wedge wire screen is self-supporting, because of the welding at each intersection

6) Low pressure-drop