Applications of Mining Sieve Bend Screen

Applications of Mining Sieve Bend Screen

Brief Introduction

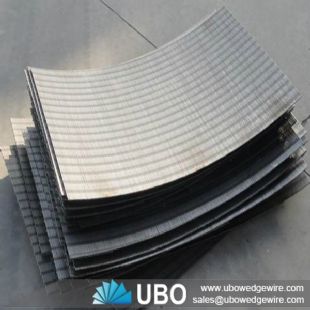

A sieve bend consists of a concave curved profile wire screen mounted in a frame with the screen openings perpendicular to the flow. A curved screen has greater capacity than a flat wedge screen due to forces exerted as material flows against the curved surface.

As slurry flows down the screen, the sharp leading edge of the wedge wire slices away a thin layer of water and small particles.

Larger particles continue down the screen surface with much of the liquid removed. Separation size is considerably smaller than screen openings, usually about one half the opening size.

Mining sieve bend screen is manufactured by wrapping and welding stainless steel V shaped profile wire cylindrically around support rods, then be made to panel screen through cutting and radian processing. Each profile wire and support rod is contacted by resistance welding. This screen boasts of firm structure, good mechanical properties, high strength, rigidity and load capacity. For the section of profile wire is V shaped, the screen slot is narrow in the above and wide in the below ,and thus be easy to leakage, wear and corrosion resistance, avoiding clogging.

On the sieve bend screen, sieve slot direction is perpendicular to the material direction. The screen has a simple and practical structure, reliable operation, good effect of dehydration, separating solids and liquids depending on centrifugal force and gravity. It is an economical and practical solid-liquid separation equipment. Sieve bend screen is widely used in coal, chemical, environmental protection industries, mainly for coal plants and mine plants moving the material to be pre-dehydration, mud, off-mediated job, classification of slime recovery. It can be also used with water cyclone supporting for moving fines material to be effective classification, dehydration, mud, off-mediated.

The Sieve bend designed by UBO is a high capacity classifying and dewatering screen to support the separation of solid and liquid slurries by incorporating fluid action, gravity and centrifugal forces. The unique feature of this product includes easy to replace deck sections, wear tear resistant, no power required, low operating cost, reversible screen and efficient in processing high capacities of material. These sieve bands are designed to deliver high dewatering performance by combining superior materials and design to maximize the performance. These screens are primarily used in the coal industry, however, they are finding uses in mineral and industrial applications.

Material

Stainless Steel:304 304L 316 316L 321

Technical Parameter

Generally the slot size of sieve bend screen is 0.3-1mm for mining screen.

Other sizes are also accepted by customers’ request.

Applications of wedge wire sieve bend screens

Sieve bend screen is widely used in coal, chemical, environmental protection industries, mainly for coal plants and mine plants moving the material to be pre-dehydration, mud, off-mediated job, classification of slime recovery. It can be also used with water cyclone supporting for moving fines material to be effective classification, dehydration, mud, off-mediated.

There are many other industries that can use sieve bend screens. For example:

• Mineral processing

• Coal washing plants

• Abattoirs

• Breweries

• Canneries

• Dairies

• Fish processing

• Fruit juice processes

• Piggeries

• Pulp and paper mills

• Sewage treatment

• Sugar mills

• Tanneries

• Wineries

• Surface water intakes

• Corn wet milling

• Coal preparation

• Gold recovery

For more information, please contact us.