filter nozzles for exchange resin facility manufacturer

| Category: | Wedge Wire Application |

|---|---|

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | Filter Nozzle |

| Application: | waste water filtration, pulp and paper as well as mineral processing applications. Wedge wire or profile screen half cylinders can be added to an aug |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of filter nozzles for exchange resin facility manufacturer

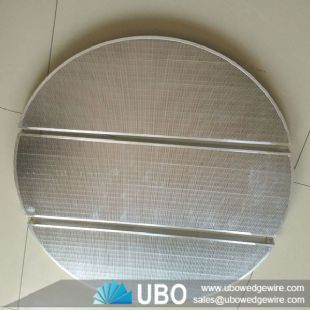

The stainless steel wedge wire screen filter nozzles( V shape) for resin traps and media air sparge is made up of stainless steel or Hastelloy C wedge wire screen. It has a structure and high open area, as well as accurate slot dimension.

Flow capacity of one pieces of filter nozzle could handle 3 m3/hour. Up to this flow capacity, almost no pressure loss happened. But to handle higher flow capacity, the pressure loss of each nozzle will be increasing accordingly. This filter nozzle type is the cheapest sellection for filter media retention.

Application for filter nozzles for exchange resin facility manufacturer :

The wedge wire screen filter nozzle can be fixed on the filtering equipment for the filteration of water petrol resin and other medium. Also it can be used in the water treatment, water softhening, conversion of sea water into fresh water, the filter of food chemistry.Small systems may be built moduarly from off-the-shelf components requiring minimal customization

Structure for filter nozzles for exchange resin facility manufacturer :

1.We use wedge-shaped profile wire in order to make the slot v-shaped.It can stop the impurities very well.

2.The wedge wire was welded on the support wire well-proportioned and have perfect roundness. Ensure the screen have bigger filter area and non obstructive, avoid the high concentration of impurities

3.After work for a period of time, the filter can be back flush.It can use for many times.

Filtering direction from outside to inside (FOTI)

Technology for filter nozzles for exchange resin facility manufacturer :

Manfre introduce advanced korea technology , the construction method used is the latest, ultra clean TiG and plasma welding system. This method of construction guarantees cartridge integrity, eliminating the risk of bypass and the presence of extractables derived from any bonding agents

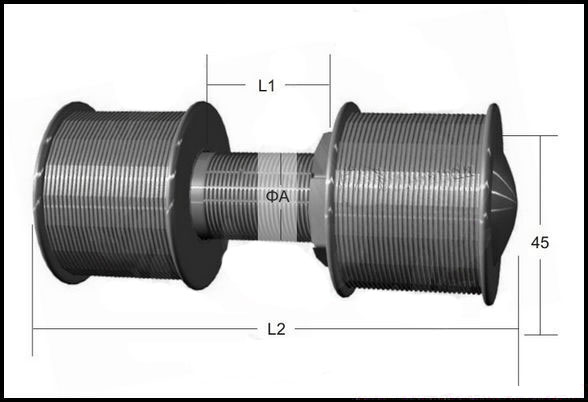

Specifications of filter nozzles for exchange resin facility manufacturer:

|

Type in catalogue |

Slots (mm) |

Thread |

ΦA (mm) |

Thread length L1(mm) |

Shaft L2(mm) |

|

A |

0.05

0.1

0.2

0.3

0.5

1 |

1 ¼ "WW |

32 |

25,30,45,+5+5... |

80,110,140,200,

250,300,350... |

|

M30*3.5 |

30 |

30 |

|||

|

G 3/4" |

26.5 |

25,30,45,+5+5... |

80,110,140,200,

250,300,350... |

||

|

1"WW |

25.4 |

20,45,+5+5... |

|||

|

M24 |

24 |

25,45,+5+5... |

|||

|

M22*1.5 |

22 |

45,+5+5... |

|||

|

G 1/2" |

21 |

20 |

80,110,140,200.. |

||

|

M20 |

20 |

45,+5+5... |

|||

|

G 3/8" |

16.7 |

20 |

Packaging and Transportation of filter nozzles for exchange resin facility manufacturer:

Order process:

1. sign a contrat

2. payment in advance

3. sample confirmation

4. sign production confirmation

5. Update production schedule by picture

6. finished products and shipping

7. customer satisfied form

Clients Visiting:

We have been in this line for many years and our products are exported to many areas around the world.

There are more than 20 licents visit our company one year. welcome to visit our company