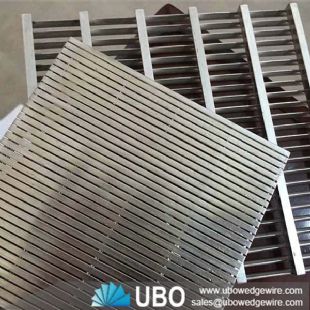

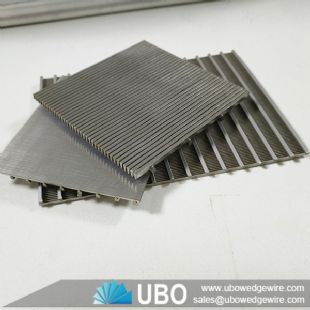

Wedge Wire Wrapped Screen Panel

| Category: | Wedge Wire Application |

|---|---|

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | Wedge Wire Screen |

| Application: | waste water filtration, pulp and paper as well as mineral processing applications. |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of Wedge Wire Wrapped Screen Panel

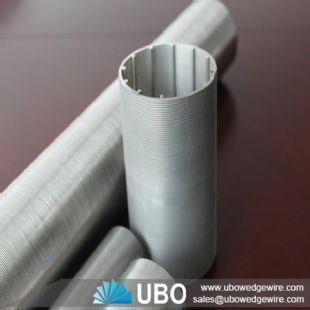

Wedge wire screen are composed of a variety of wedge wire configurations and constructed in a spiral shaped form where the support profile is wrapped spirally by the surface. Anping BF WIRE MESH uses stainless steel grade of 304, 316 and 316L sourced out from well-known stainless steel manufacturing companies.

Application for Wedge Wire Wrapped Screen Panel:

This product can be widely used in mining, coal, petroleum, fertilizer, grain, salt industry, environment protection, etc. Sieving liquid, powder and other materials. Petroleum, chemical industry, metallurgy, mining, pharmaceutical purification, drilling liquid purification and other industries use.

Advantage for Wedge Wire Wrapped Screen Panel:

1) A continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone.

2) A Vshaped profile wire which avoids clogging and ensures an uninterrupted flow.

3) A uniform and efficient well development due to the continuous slot opening.

4) Ladder-like wire welded screens have a strong structure and high open area, as well as accurate slot dimension.

5) Ladder-like wire welded screens have the features of easy backwashing, last long, safety and reliability as well as low comprehensive cost.

Features for Wedge Wire Wrapped Screen Panel:

1) Screens with high open area are more suitable for the construction of high-quality water wells, oil wells and gas wells.

2) Low cost operation

Screens with high open area shall favor groundwater infiltration. Abundant water shall reduce the water levels down, thus to save energy consumption.

3) Reduce the abrasion of the pump

Under the same condition, high open area can make the speed of groundwaters entering into the screen much slower than any other filtration apparatus, which will avoid sands entering into screen because of high pressure, thus reduce the abrasion of the pump.

4) Extend the life span of wells

Comparatively, groundwaters entering into screen with higher open area is much easier than the entering into lower open area screen. The slow water flow shall extend the life span of wells.

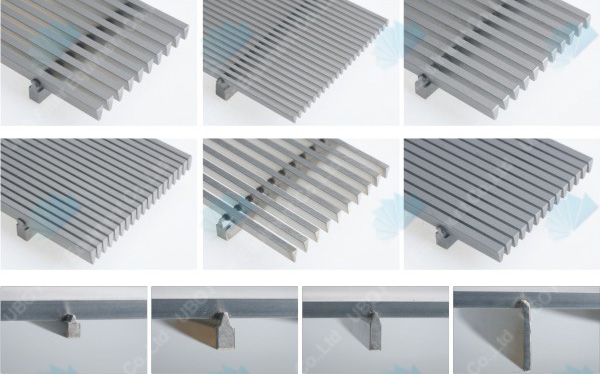

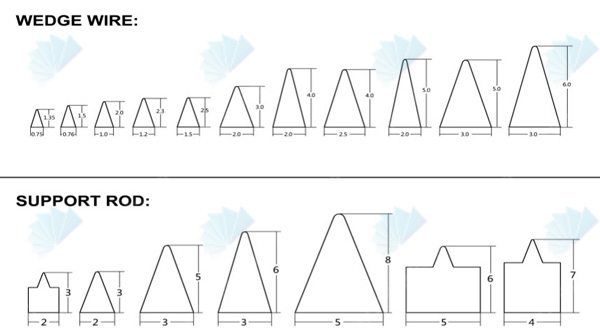

Specifications of Wedge Wire Wrapped Screen Panel:

|

Surface Profile |

W

|

H

|

Material |

|

10S |

0.75

|

1.425

|

S304,S316L Hastelloy, Monel alloy of nickel and titanium, and other stainless steel |

|

11SL |

10.75

|

1.8

|

|

|

22S |

1.8

|

3.7

|

|

|

4S |

0.45

|

1.2

|

|

|

50SL |

3.4

|

7.5

|

|

Surface Profile

|

W

|

H

|

Material

|

|

Q22

|

2

|

2.28

|

S304,S316L Hastelloy, Monel alloy of nickel and titanium, and other stainless steel |

|

Q35

|

3

|

5

|

|

|

Q53

|

4

|

3

|

|

|

D56

|

4

|

5.6

|

|

|

D45

|

3.8

|

6.0

|

Packaging and Transportation of Wedge Wire Wrapped Screen Panel: