Stainless Steel Wedge V Wire Wrap Screen for Filtration Elements

| Category: | Wedge Wire Application |

|---|---|

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | Wedge Wire Screen |

| Application: | waste water filtration, pulp and paper as well as mineral processing applications. Wedge wire or profile screen half cylinders can be added to an aug |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of Stainless Steel Wedge V Wire Wrap Screen for Filtration Elements

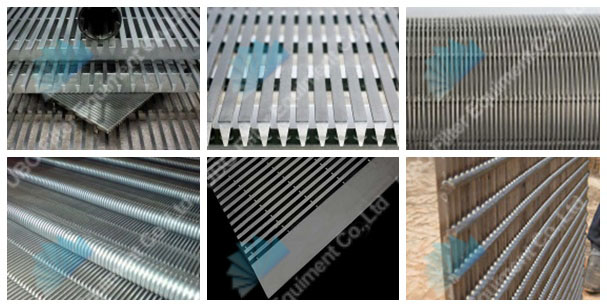

Wedge wire screen panels have continuous slot openings that widen inwardly. This makes the screen self-cleaning by allowing "near slot size" particles to pass through the screen rather than plug the opening. And the products are made by continuously winding a wrap wire onto a frame of support rods. This is done on precision built, electronically controlled machinery which ensures consistently high strength, precise slot openings and product durability.

Applications for Stainless Steel Wedge V Wire Wrap Screen for Filtration Elements:

Flat panel screen can be parts of deep well pumps or submersible pumps; can be used for water treatment equipment, environment protection, the sea water desalination, water softening treatment, oil and chemical processing; terminal filtration for petroleum products, filtration for chemical acid and soda liquid, for alcohol and other organic solvents recycle filtration.

Features for Stainless Steel Wedge V Wire Wrap Screen for Filtration Elements:

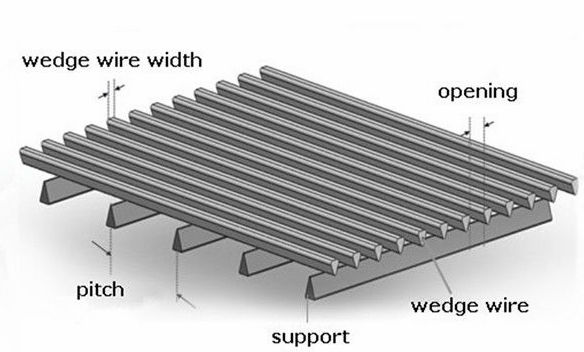

Wedge wire screen is made up of rods and profile wire.The rod can be round wire,triangular wire or trapezoid wire.The profile wire is triangular wire (V-shaped wire).Wedge wire screen has a structure and high open area,as well as accurate slot dimension.At the same time,water well screen have heat-resisting,anti-corrosive,good machine capability,last long,safety and reliability and so on characteristics.It can be used in many kinds of medium filtering.

Advantages for Stainless Steel Wedge V Wire Wrap Screen for Filtration Elements:

-- A continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone.

-- A “V”shaped profile wire which avoids clogging and ensures an uninterrupted flow.

-- A uniform and efficient well development due to the continuous slot opening.

-- Ladder-like wire welded screens have a strong structure and high open area, as well as accurate slot dimension.

-- Ladder-like wire welded screens have the features of easy backwashing, last long, safety and reliability as well as low comprehensive cost.

Specifications of Stainless Steel Wedge V Wire Wrap Screen for Filtration Elements:

|

Specification (wedge wire): |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

|

Specification (support rod): |

Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

|

Note: other specifications available as per request |

|

|

Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material: |

galvanized low carton (LCG), stainless steel (304,316 etc.) |

|

Length |

up to 6 meters. |

|

Diameter |

from 25mm to 1200mm. |

|

End connection |

Plain beveled ends, flanged or threaded couplings |

Packaging and Transportation of Stainless Steel Wedge V Wire Wrap Screen for Filtration Elements: