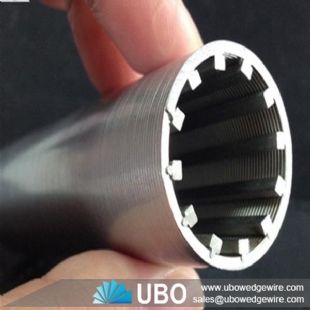

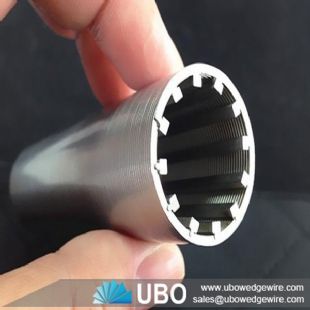

stainless steel wire wrap well screen slotted pipe

| Category: | Wedge Wire Pipe&Cylinder |

|---|---|

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | Wedge wire screen cylinders |

| Application: | water treatment, oilfield, mining, food industry, chemical industry, papermaking industry, decoration. |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of stainless steel wire wrap well screen slotted pipe

The wire wrapped well screen has a favorable reception in the oil fields. Its unique design allows the hierarchical sand control. Accordingly, it comes with ultra-high sand prevention effect. Associated with excellent permeability, good strength, high reliability, as well as good resistance to deformation and corrosion, this screen is the optimal sand-prevention product. Its raw materials are carbon steel and qualified stainless steel.

Applicable Conditions for stainless steel wire wrap well screen slotted pipe:

The slotted pipe is suitable for the following completion methods of the vertical or horizontal well, deviated well, and multilateral well. The terrane should be of loose medium or coarse sand.

1. Slotted liner completion

2. Open-hole gravel pack completion

3. Casing gravel pack completion

4. The pipe sealed within the screened pipe

Features for stainless steel wire wrap well screen slotted pipe:

1. The wire wrapped well screen designed with keystone slots has self-clean function. Its holes are made from the natural mineral regenerated synthetic micro-porous crystalline materials. Thus, our product offers superfine filtration effect.

2. Its good lipophilic property helps prevent the screen from being blocked.

3. Our easily used product requires low cost but high machining precision. The slot width is no less than 0.15mm, and the tolerance is of ±0.03mm.

4. This type of screen is applicable for any kind of geological conditions. Thesmooth slot cavity is coated with the 0.1 to 0.2mm thick anticorrosive hardening layer, which allows the strength three times more than that of the base tube.

5. It is applicable for the sand prevention of high-viscosity oil. It offers high oil filtering rate.

Manufacturing Process for stainless steel wire wrap well screen slotted pipe:

1. Determine the relevant parameters according to the pipe which will be processed. Then, choose the required software in accordance with the parameters.

2. Make sure the gas distribution index of the equipment.

3. Start the cutting operation when the equipment meets the index requirement. Before processing, the pipe should be surface treated. It also should be cooled during the cutting process. Meanwhile, the iron residue or oxidizing material inside the pipe must be removed as well.

4. After cutting, the pipe will be inspected. If qualified, it will be shipped after the completion report preparation. Otherwise, it will be sent to the waste collection rack. Unlike the machine tool, the laser cutter allows the slotted pipe to be 0.2mm to 0.3mm wide. With this cutting method, the finished product has an extremely low defect rate of no more than 5%.

Specifications of stainless steel wire wrap well screen slotted pipe:

|

Specification (wedge wire):

|

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70

Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00

|

|

Specification (support rod):

|

Width(mm): 2.30 3.00 3.30 3.70

Height(mm): 2.70 3.60 4.70 5.60 6.30

Round: From 2.50mm to 6.0mm

|

|

Note: other specifications available as per request

|

|

|

Slot size

|

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request.

|

|

Material:

|

galvanized low carton (LCG), stainless steel (304,316 etc.)

|

|

Length

|

up to 6 meters.

|

|

Diameter

|

from 25mm to 1200mm.

|

|

End connection

|

Plain beveled ends, flanged or threaded couplings

|

Packaging and Transportation of stainless steel wire wrap well screen slotted pipe: