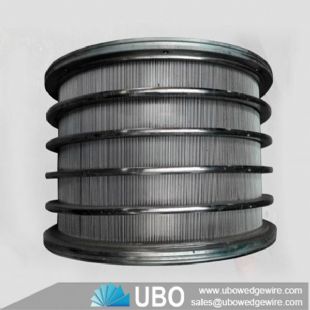

stainless steel wedge wire screen cylinder

| Category: | Wedge Wire Pipe&Cylinder |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | wedge wire screen |

| Application: | water treatment, oilfield, mining, food industry, chemical industry, papermaking industry, decoration. |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of stainless steel wedge wire screen cylinder

Stainless steel wedge wire screen cylinder as one type wedge wire screen is known as the equipment for filtration or separation in chemical or industry fields. But it is also used in architecture for decoration application.

The stainless steel wedge wire screen cylinder . It is a high precesion Fitler cylinder. The advanced production technology gives the cylinders an everage filtering slot and Smooth surface.

Advantages of stainless steel wedge wire screen cylinder

flatness to within tight tolerances

no weakening of the welds, because of flattening (and no stress corrosion problems as a result)

accurate distance between support profiles

possibility of different support wires in one screen

possibility of variable spacing between support wires in one screen

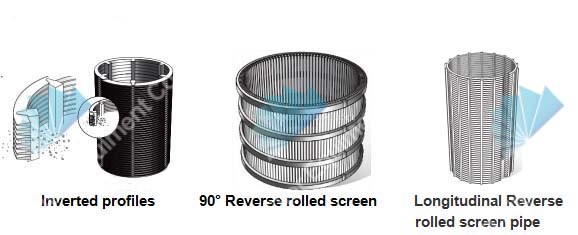

Constructions of stainless steel wedge wire screen cylinder

A combination of different support profiles and pitches within one flat screen is possible

Variable spacing between support wires in one screen

Curved screens; curve direction and filtration direction are to be determined by the customer.Frames and reinforcements can be designed and calculated on request, provided that we know the temperature, supports and differential pressure.

Usage of stainless steel wedge wire screen cylinder

Be suitable for all kinds pressure screen in pulp making system and paper making system.

The stainless steel wedge wire screen cylinder is perforation/hole or slot/wedge wire structure designed to achieve high efficiency screening of recycled, mechanical, and paper pulp fiber. The patent-pending design features a robust mechanical assembly and a high-precision wire positioning system to minimize slot width deviation.

Specifications of stainless steel wedge wire screen cylinder:

|

No. |

(mm)TYPE |

OD (mm) |

ID (mm) |

Support wire Number |

Filter direction |

|

1 |

SRD 40 |

40 |

31 |

8/10 |

FOTI/FITO |

|

2 |

SRD 45 |

45 |

36 |

10/12 |

FOTI/FITO |

|

3 |

SRD 48 |

48 |

38 |

12 |

FOTI/FITO |

|

4 |

SRD 60 |

60 |

51 |

12 |

FOTI/FITO |

|

5 |

SRD 70 |

70 |

61 |

12/18 |

FOTI/FITO |

|

6 |

SRD 85 |

85 |

76 |

18 |

FOTI/FITO |

|

7 |

SRD 110 |

110 |

101 |

24 |

FOTI/FITO |

|

8 |

SRD120 |

120 |

111 |

24 |

FOTI/FITO |

Packaging and Transportation of stainless steel wedge wire screen cylinder: